5-Axis to the Future - Machining Technology Its New Benefits

The 5-Axis Turning Point

Traditionally, complex components required multiple setups on 3-axis or 4-axis machines, increasing lead time, the chance for error, and operator dependency. 5-axis machining consolidated that into a single setup, enabling manufacturers to machine intricate geometries with higher precision and lower cycle times.

Suddenly, parts that were once reserved for aerospace and defense could be produced economically in smaller batches for medical, automotive, and consumer sectors. The result? A dramatic boost in efficiency, flexibility, and competitiveness.

But as the technology matured and adoption widened, a new question emerged: What’s next?

How 5-Axis Changed the Industry

1. Consolidated Machining Steps

One of the most immediate benefits was reducing multi-setup operations. Complex parts that required manual repositioning and re-clamping could now be produced in one go—improving consistency and accuracy.

2. Improved Surface Finish and Tool Life

Better control of tool orientation reduced the need for long tool overhangs, improving surface finishes and reducing wear.

3. Enabled Advanced Design and Engineering

Engineers began designing parts specifically for 5-axis capabilities—moving from “design for manufacturability” to “design for performance.”

4. Increased Competitiveness

Shops that adopted 5-axis early gained a market edge, attracting high-precision jobs and increasing their ability to serve advanced industries.

The Best 5-Axis Available For Operations

1. For Beginners: Haas UMC-500

Category: Entry-Level / Accessible 5-Axis

Best For: Job shops or small manufacturers stepping into 5-axis for the first time

Why it’s a standout:

The Haas UMC-500 combines a compact footprint with easy-to-learn controls (especially for those familiar with the Haas ecosystem). It offers robust capabilities without overwhelming complexity.

Features:

- Integrated rotary trunnion table

- 30" x 20" x 20" travel

- User-friendly Haas control

- Reasonable price point

Ideal Use Cases:

-

Prototypes, aluminum components, low- to mid-complexity parts

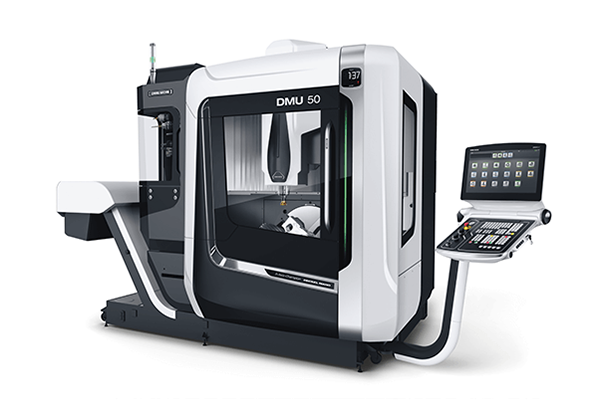

2. The All-Rounder: DMG MORI DMU 50 3rd Gen

Category: Versatile / Mid-Market Professional

Best For: Shops needing flexibility to handle a wide range of part geometries and materials

Why it’s a standout:

The DMU 50 is often considered the benchmark for mid-level 5-axis machining. It’s widely adopted across industries for its balance of precision, rigidity, and adaptability

Features:

- Swivel rotary table (tilt: -35° to +110°)

- High-speed spindles up to 20,000 rpm

- Heidenhain or Siemens control

- Advanced cooling and chip management

Ideal Use Cases:

-

Aerospace brackets, medical parts, precision tooling

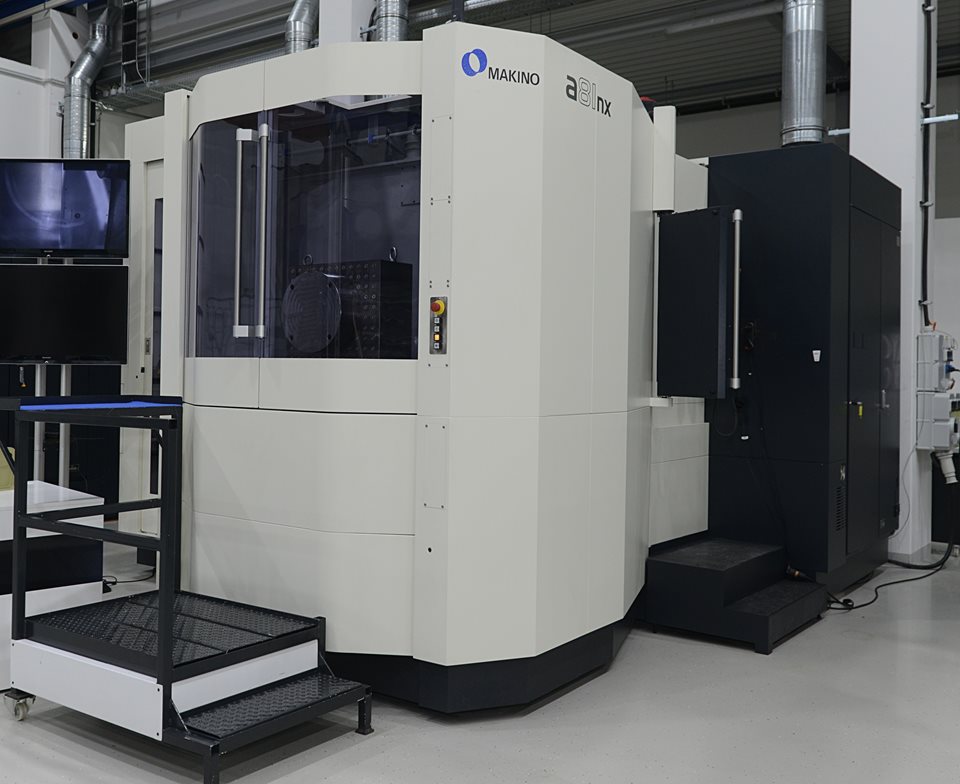

3. Most Technologically Advanced: Makino T1 or T6

Category: High-End / Aerospace & Hard Metal Powerhouse

Best For: High-stakes industries like aerospace, defense, and energy where precision, rigidity, and material performance are critical

Why it’s a standout:

Makino’s T-series machines are designed for titanium and Inconel machining. With extreme rigidity, adaptive control, and advanced thermal stability, this is a machine built for the bleeding edge.

Features (T1/T6):

- 5-axis simultaneous machining with automatic pallet changers

- 12,000+ rpm HSK-A100 spindle

- Active damping and high torque for hard materials

- Industry-grade automation readiness

Ideal Use Cases:

-

Jet engine components, satellite structures, deep-cavity tooling

The Next Frontier in Machining Equipment

As 5-axis becomes more commonplace, machine builders and manufacturers are already pushing the envelope. Here's what the future may look like:

1. Multi-Spindle, Multi-Turret Machines

- Two-spindle machines (or more) are becoming popular in high-volume, high-mix production, enabling simultaneous machining on both ends of a part—or even simultaneous part production.

- Turrets equipped with live tooling on both spindles reduce transfer time, and machines equipped with Y-axis and sub-spindle integration support complex, complete part machining in a single setup.

2. 9-Axis, 12-Axis, and Beyond

- Machines with 9+ axes aren’t gimmicks - they're answering real-world needs in sectors like aerospace, medical implants, turbine components, and defense.

- These setups often combine turning, milling, drilling, and gear hobbing - all in one machine.

3. Hybrid Machines

- Additive + subtractive machines are emerging—capable of building up material using 3D printing, then finishing it with high-precision cutting tools. This will reshape prototyping and repair workflows.

- Laser-assisted machining is also gaining traction for hard-to-cut materials like ceramics and hardened alloys.

4. Intelligent Automation & AI Integration

- Machine tools are evolving into self-monitoring systems that adjust feedrates, toolpaths, or even maintenance schedules based on real-time data.

- AI-enabled CAM software can suggest optimal toolpaths or predict tool breakage before it happens.

5. Digital Twin Integration

- Advanced simulations and digital twins now allow machinists to preview setups, stress-test fixtures, and avoid collisions—all before cutting a single chip.

- This shortens setup time and reduces scrap, especially in high-mix/low-volume production environments

What This Means for the Industry

For shops: High-mix, low-volume manufacturing is becoming more practical and profitable. Multi-axis machines mean fewer setups, shorter lead times, and better part consistency.

For OEMs: The ability to design without the constraints of traditional machining opens new possibilities in lightweighting, part consolidation, and performance optimization.

For machinists and engineers: The bar is higher. Technical knowledge of multi-axis programming, CAM software, and machine kinematics is quickly becoming essential.

Preparing for a Multi-Axis Future

5-axis machining was a revolution. What comes next is an evolution—toward hyper-flexible, multi-functional, and intelligently automated machines that don't just make parts faster, but make better parts, smarter.

The future of machining lies not in more axes alone—but in how seamlessly they’re integrated into a connected, intelligent manufacturing ecosystem.

Whether it's twin-spindle turn-mill centers or 100-axis robots machining lattice structures, the message is clear: complexity is no longer a barrier—it’s a blueprint.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.