Produce more without buying new machine

Learn how with MDCplusDMG MORI: History, Best CNCs and Advantages

DMG MORI History

DMG MORI is a leading global manufacturer of high-precision machine tools, known for its innovative technology and comprehensive solutions in the manufacturing sector. The company has a rich history, originating from the merger of two prominent machine tool manufacturers: Mori Seiki and Gildemeister AG (DMG).

Established in 1948, Mori Seiki began as a textile machinery producer before transitioning to machine tool manufacturing in the late 1950s. The strategic partnership with DMG in 2009 led to the formation of DMG MORI, which has since become the largest machine tool builder in the world, with operations in 43 countries and over 116 sales and service locations.

Most popular machines from DMG MORI

DMG MORI is renowned for several signature machine models that exemplify its commitment to precision, flexibility, and technological advancement:

DMU Series (5-Axis Machining Centers)

DMG MORI DMU 40 and DMU 50 models

View through DMU's portal window

Features: Offers simultaneous 5-axis machining capabilities, accommodating complex geometries and large workpieces.

Technical Details: Models like the DMU 50 can handle components weighing up to 300 kg with high precision. They feature advanced cooling systems and robust spindle designs that allow for speeds up to 20,000 rpm.

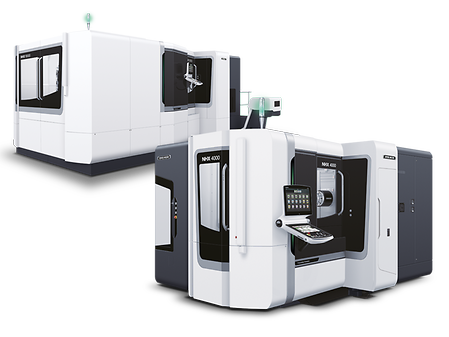

NHX Series (Horizontal Machining Centers)

DMG MORI HNX 4000 overview

Spindle unit and worktable of HNX

Features: Known for high-speed performance and efficiency in machining complex parts.

Technical Details: The NHX 4000 boasts a speedMASTER motor spindle capable of 20,000 rpm with rapid acceleration rates of up to 1.2 g. It also includes automation-ready features for enhanced productivity.

NTX Series (Turn & Mill Machines)

DMG MORI NTX 1000 and larger NTX 3000

Process of new NTX 1000 machining a part

Features: Combines turning and milling operations in one setup for complete machining.

Technical Details: The NTX series offers dynamic linear drives and can perform 6-sided turning and 5-axis milling in a single clamping, enhancing accuracy and reducing cycle times.

CMX Series (Entry-Level Machining Centers)

DMG MORI CMX 50U for great start

Inner workspace of DMG MORI CMX Series

Features: Provides an affordable entry point into high-quality CNC machining.

Technical Details: Designed for versatility, these machines can be configured for various applications while maintaining high precision.

DMG MORI Competitive Advantages

DMG MORI stands out in the competitive landscape of machine tool manufacturing due to several key factors:

- Innovative Technology: DMG MORI integrates cutting-edge technologies such as digital twins, artificial intelligence, and IoT into their machines. Their CELOS software platform enhances user interaction and process management.

- Holistic Solutions: The company emphasizes "Machining Transformation" (MX), which combines process integration, automation, digital transformation, and green initiatives to optimize manufacturing efficiency.

- Customization and Flexibility: DMG MORI machines can be tailored to meet specific customer needs through modular designs that allow for various configurations and integrated automation solutions.

- High Precision and Quality: The machines are built with robust structures that ensure stability during operation, resulting in exceptional accuracy even at high speeds. Features like direct path measuring systems further enhance precision.

- Comprehensive Support: DMG MORI offers extensive customer support throughout the machine's lifecycle, including training, maintenance, and spare parts services.

In summary, DMG MORI's commitment to innovation, quality manufacturing solutions, and customer-centric services solidifies its position as a leader in the CNC machining industry. Their signature machines not only meet but often exceed industry standards for performance and reliability.

Image and logo copyright - © DMG MORI

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.