FANUC at FABTECH 2025: Practical Robots That Bring Innovation

At this year’s FABTECH, FANUC made one thing very clear: automation is no longer about impressing with size or complexity. It’s about solving real, everyday production problems — fast setups, fewer hands, smaller footprints, and smarter motion. Their 2025 lineup delivers just that.

Live Welding with Collaborative Cobots

FANUC ran a full demo with two CRX-10iA cobots assembling, welding, and deburring a washer-nut component. One held the part using a positioner, the other handled the weld. Then a CRX-30iA equipped with FANUC’s 3DV/200 vision camera handled part removal — all in one smooth, coordinated loop.

If you’re working with high-mix, low-volume production, this kind of flexible cell hits the sweet spot: fast redeployment, intuitive hand guidance, drag-and-drop programming, and zero reliance on programming specialists.

Coordinated Multi-Arm Welding for Big Parts

Another strong showing was the M-950/500F-28A robot presenting an excavator bucket to two Arc Mate 25/18D robots. While the Arc Mates simulated welding seams, the M-950 dynamically repositioned the bucket for perfect weld access.

This wasn’t just for show — it’s a real blueprint for shops needing to automate large, hard-to-handle parts without sacrificing quality or requiring oversized fixtures.

Compact Cells, Full Uptime

A big crowd-pleaser was the multi-station arc welding cell: a CRX-10iA/L on a 7th-axis rail moving between two operator stations. One side was welding while the other loaded the next part — continuous operation, minimal footprint.

This is a smart solution for manufacturers dealing with space constraints but still aiming for lights-out automation. Safety, efficiency, and speed in one package.

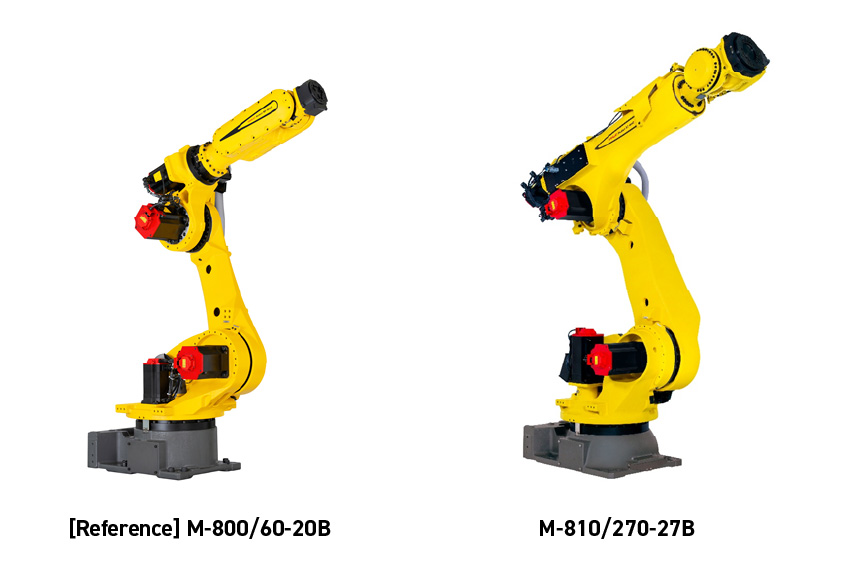

Wet Machining, Robot-Style

FANUC also showed off its newest M810/270F-27B robot — this one built for tough machining tasks. It milled and drilled aluminum stock live, proving that robots can handle wet machining in dirty, high-load environments with accuracy and speed.

For machine shops looking to automate the messy, first-stage cuts or reduce human risk in coolant-heavy zones, this one deserves a second look.

Smarter CNC & Laser Integration

In addition to robots, FANUC’s booth featured its latest Alpha i-D Servo System and CNCs optimized for laser cutting. Combined with smoother path control and advanced diagnostics, these systems are built to reduce waste and dial up precision — especially for thin metals and detailed patterns.

Visual Painting Gets an Upgrade

At FANUC’s paint booth, a CRX-10iA/L Paint Cobot used 3D vision to paint electric guitar bodies — tracking them live as they moved. Another cobot, the CRX-20iA/L, managed part loading and unloading using FANUC’s iRPickTool software.

What’s notable here is the ability to coat delicate, multi-shape parts without jigs or reprogramming — ideal for automotive, aerospace, or consumer goods.

The automation tech on display wasn’t hypothetical or overly customized. It was fast, reconfigurable, and designed for small-to-mid-sized manufacturers trying to stay lean and competitive. You don’t need a team of robotics engineers to make it work. You just need a real problem — and a system that solves it.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?