+20% FANUC CNC efficiency within a month

Start your free demoFANUC: Iconic CNC Systems Pioneering Precision in Automation

Few names resonate as powerfully as FANUC among those who are seeking for manufacturing automation. Renowned for its cutting-edge CNC (computer numerical control) systems, FANUC has cemented its position as a global leader, with over 5 million installations worldwide. These systems are the backbone of manufacturing sectors ranging from aerospace to medical devices, enabling unparalleled precision, efficiency, and innovation.

FANUC CNC Systems: The Engine of Modern Manufacturing

FANUC’s CNC systems are synonymous with reliability, speed, and performance. Designed to maximize machine tool capabilities, they empower manufacturers to achieve high-speed machining, superior surface finishes, and seamless operation. Their adaptability spans high-volume production lines to bespoke, complex part manufacturing, making them indispensable in industries demanding precision, such as:

- Aerospace (turbine blades, structural components)

- Automotive (engine parts, transmissions)

- Medical Devices (implants, surgical tools)

- Construction (heavy machinery components)

FANUC-based equipment is in top-3 of most popular among our clients

Flagship CNC Systems: Innovation at Its Core

FANUC’s product portfolio caters to diverse manufacturing needs, from entry-level shops to advanced facilities. Below are three standout systems redefining industry standards:

1. Advanced CNC Series 30i/31i/32i-B Plus: Mastery of Complexity

- Premium Control for Advanced Machinery: Optimized for 5-axis machining, this series delivers faster cycle times and enhanced surface finish accuracy.

- Smart Features: AI-driven thermal compensation and vibration control minimize errors, while a 15-inch touchscreen simplifies complex operations.

- Ideal For: Aerospace and automotive sectors where intricate geometries and tight tolerances are critical.

2. 0i-MF Plus CNC Series: Efficiency Redefined

- User-Centric Design: Boasts a customizable interface and intuitive navigation, reducing training time.

- Performance Boost: Optimizes spindle performance and slashes sequencing delays, ideal for high-volume production (e.g., automotive components).

- Compact Power: Despite its smaller footprint, it supports multi-tasking machines and IoT connectivity for smart factories.

3. Series 500i-A CNC: The Future of 5-Axis Machining

- Integrated 5-Axis Technology: Streamlines complex machining with synchronized motion control and collision avoidance.

- Enhanced Processing: A next-gen CPU and iHMI2 interface accelerate data handling, perfect for medical device prototyping or mold manufacturing.

- Security & Scalability: Features advanced cybersecurity protocols and supports AI-driven predictive maintenance.

Versatility Across Industries

FANUC’s CNC systems thrive in diverse environments:

- High-Volume Production: The 0i-MF Plus ensures rapid, consistent output for automotive assembly lines.

- Customized Precision: The 30i/31i/32i-B series handles low-volume, high-complexity parts like aerospace components.

- Adaptability: Seamless integration with robotics and IoT platforms future-proofs manufacturing workflows.

Empowering the Workforce: Training and Support

Beyond hardware, FANUC invests in human capital through CNC training solutions. Their simulators and virtual tools allow operators to master real FANUC equipment without halting production. This commitment to education ensures manufacturers can upskill teams while maintaining productivity, giving a critical advantage in an era of skilled labor shortages.

FANUC’s Enduring Impact on World Machining

FANUC’s CNC systems are more than tools, being the catalysts for industrial progress. By blending reliability with innovation, products like the Series 30i and 500i-A empower manufacturers to push boundaries in precision and efficiency. As industries evolve toward smarter, more connected factories, FANUC’s focus on user-friendly interfaces, security, and adaptability ensures it remains at the forefront of automation.

From its 5 million installations to its visionary training programs, FANUC’s legacy is one of transforming manufacturing challenges into opportunities - one precise cut at a time.

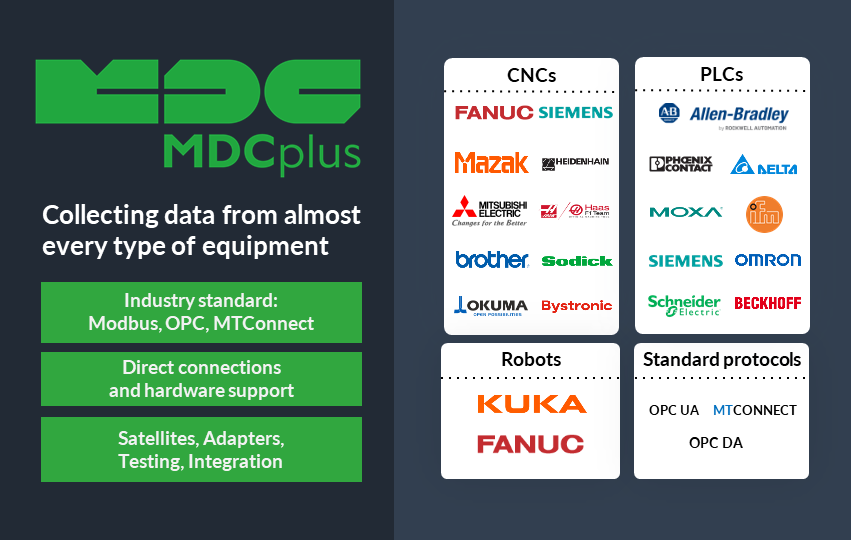

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.