Pair FANUC with MDCplus

Double your CNC efficiencyUnderstanding FOCAS: A Tech Guide to FANUC’s Open CNC API

If you’re a technician working with CNC machines or a beginner engineer stepping into the world of industrial automation, you’ve likely heard of FANUC—a name synonymous with precision and reliability in manufacturing. One of FANUC’s lesser-known but incredibly powerful tools is FOCAS, short for FANUC Open CNC API Specification. Don’t let the acronym scare you - it’s simpler than it sounds, and it’s a game-changer for anyone working with CNC (Computer Numerical Control) systems. Let’s break it down in a way that’s easy to digest, with practical insights for technicians and a clear path for new engineers.

What Is FOCAS?

FOCAS is like a backstage pass to a FANUC CNC machine’s brain. It’s a set of software tools—specifically, a collection of library files (called DLLs)—that lets you connect to and pull data from FANUC CNC controllers. Think of it as a translator: it takes the complex language of the CNC system and turns it into something a computer program or application can understand and use.

At its core, FOCAS is a protocol that works over Ethernet or a high-speed connection called HSSB (High-Speed Serial Bus). It’s been around for years, built into most modern FANUC controllers (think machines from the last 10-15 years), and it’s designed to give you access to nearly everything happening inside the CNC—without needing extra hardware or complicated workarounds.

Where Is FOCAS Used?

You’ll find FOCAS in factories, workshops, and production lines all over the world—anywhere FANUC CNC machines are cutting, milling, turning, or grinding. FANUC controllers power equipment from big-name machine tool brands like Haas, Doosan, Tsugami, and Citizen, so FOCAS is a common thread across diverse industries: automotive, aerospace, medical device manufacturing, and more.

It’s not just limited to FANUC machines, either. Some non-FANUC equipment can tap into FOCAS if it’s paired with a FANUC controller. Whether you’re in a small shop tweaking a single lathe or a massive plant monitoring dozens of machines, FOCAS is there to bridge the gap between the machine and the digital world.

What Can FOCAS Do? Practical Uses for Technicians and Engineers

Here’s where it gets exciting - FOCAS is incredibly versatile. It’s like having a Swiss Army knife for CNC data. Let’s look at some of its key uses, with examples that’ll resonate whether you’re troubleshooting on the shop floor or designing a system from scratch.

- Real-Time Machine Monitoring

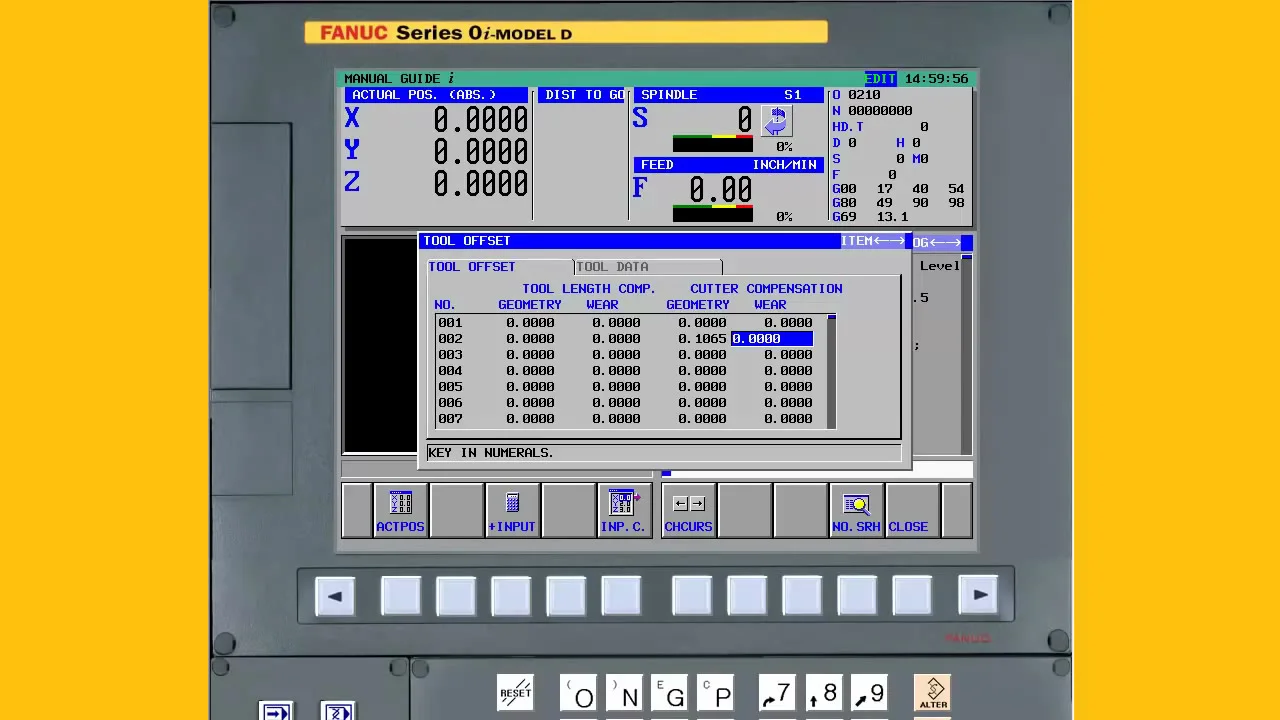

Want to know if a machine is running, idle, or throwing an alarm? FOCAS can tell you. It pulls live data like spindle speed, feed rates, and machine status. For a technician, this means you can spot a problem—like a sudden stop—without standing at the control panel all day. For an engineer, it’s the foundation for building dashboards or apps to track shop floor performance. - Part Count Tracking

How many parts has the machine churned out today? FOCAS grabs part count info straight from the controller. Technicians can use this to verify production quotas, while engineers might feed it into a system to predict maintenance needs—like when a tool’s about to wear out after 1,000 cuts. - Program Management

FOCAS lets you read, upload, or even delete CNC programs remotely. Imagine you’re a technician fixing a bad cut: you can pull the active program name and check if it’s the right one without digging through menus. Engineers can take it further—writing software to automate program swaps for different jobs. - Alarm and Diagnostics

When a machine throws an error, FOCAS delivers the alarm number and text. A technician can use this to pinpoint why the spindle stopped (say, a tool offset issue), while an engineer might log these alarms to spot recurring problems across a fleet of machines. - Customization and Automation

Here’s the fun part: FOCAS isn’t just for reading data—it can control things too. Technicians might use it to tweak settings like feed overrides remotely. Engineers can go wild, coding custom apps to start programs, adjust parameters, or even integrate CNCs with robots or IoT platforms.

How Does It Work in the Real World?

Picture this: You’re a technician on a busy shop floor. A milling machine keeps stalling, and the operator swears it’s not their fault. You plug an Ethernet cable into the FANUC controller’s embedded port (usually behind the screen or in the electrical cabinet), connect it to a laptop running a FOCAS-based tool, and boom—you see the machine’s in an alarm state because of a coolant issue. You reset it remotely, and production’s back on track. No fuss, no standing around.

For a beginner engineer, it’s just as practical. Say you’re tasked with setting up a simple monitoring system. You grab the FOCAS library (available from FANUC for a small fee—around $100), hook it into a Visual Studio project, and write a few lines of code to display spindle speed. Connect it via Ethernet, and you’ve got a live feed on your screen. It’s that straightforward to start, but the possibilities grow as you dig deeper.

Why Technicians and Engineers Love It

- No Extra Hardware: If your FANUC CNC has an Ethernet port (standard since the 18i-B series), you’re good to go. No need for clunky adapters like with older machines.

- Time-Saver: Pull data or tweak settings without wrestling with the control panel’s buttons.

- Flexibility: Whether you’re troubleshooting one machine or linking a dozen to a network, FOCAS scales with you.

- Future-Proof: It ties into modern standards like MTConnect or OPC-UA, so engineers can build systems that evolve with the industry.

Tips for Beginners

If you’re new to this, don’t worry—FOCAS is approachable with a little guidance:

- Check Your Machine: Press the [SYSTEM] key on the FANUC controller, scroll to “ETHPRM” or “EMBED PORT,” and see if Ethernet’s active. If it is, FOCAS is likely supported.

- Grab the Tools: Buy the FOCAS Library CD from FANUC (part number A02B-0207-K737). It’s got the DLLs and docs you’ll need.

- Start Simple: Use a prebuilt tool like MDCplus to extract and analyze data or write a basic script to read machine status. Build from there as you get comfortable.

- Ask for Help: FANUC reps or online forums (like CNCzone) are goldmines for troubleshooting.

A Word of Caution

FOCAS is powerful, but it’s not plug-and-play out of the box. Technicians might need a bit of setup help from an IT guy to get the network right. Engineers, be ready to wrestle with some coding—it’s not as user-friendly as drag-and-drop software. And if your machine is ancient (pre-2000s), you might need a retrofit or extra options turned on by FANUC.

FOCAS is your ticket to unlocking the full potential of FANUC CNC machines. For technicians, it’s a trusty tool to keep things running smoothly. For beginner engineers, it’s a launchpad to explore automation and data-driven manufacturing. It’s not just about collecting numbers - it’s about making your job easier, your machines smarter, and your shop more efficient. So next time you’re near a FANUC controller, plug in, fire up FOCAS, and see what it can do for you. You’ll wonder how you ever managed without it.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.