Exploring free solutions? Try MDCplus

Try it yourself Get guided demoIEC 62443 Explained for Manufacturers - Industrial Automation

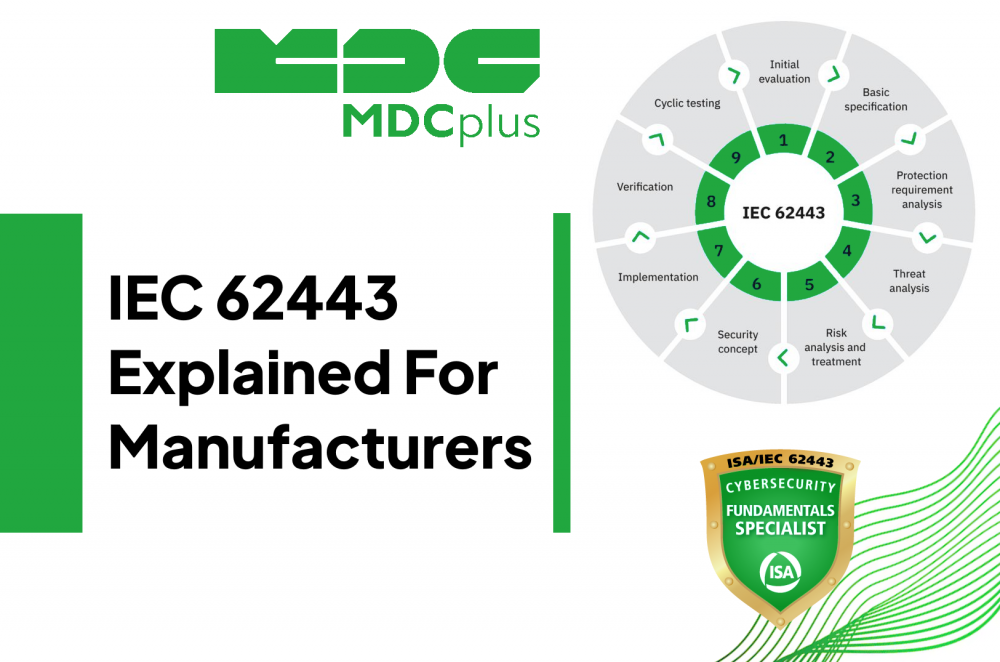

A simple guide to the most important cybersecurity standard in modern manufacturing. Manufacturing is now fully connected. CNC machines, robots, PLCs, HMIs and SCADA communicate with each other and with business systems. This connectivity improves efficiency, but it also exposes plants to cyber risks that can stop production instantly. IEC 62443 is the global standard that defines how to secure industrial environments.

What Is IEC 62443 in Simple Terms?

IEC 62443 is a family of cybersecurity standards for industrial automation. It tells manufacturers how to:

- Protect machines, PLCs, robots and HMIs

- Segment networks so problems cannot spread

- Secure remote access and maintenance

- Manage updates and patches

- Train people to avoid cyber incidents

- Keep production running even during attacks

Think of it as a structured playbook that makes OT environments safe and resilient.

Why Does IEC 62443 Matter for Manufacturing Plants?

Because modern factories rely on connected machines. Cyber incidents no longer affect only office PCs. They can:

- Halt production

- Damage equipment

- Corrupt recipes or CNC programs

- Mislead operators

- Interrupt safety systems

- Leak intellectual property

A single ransomware event can cost millions in lost output. IEC 62443 provides a framework to prevent that.

What Are the Core Parts of IEC 62443?

The standard is divided into four major groups. Here is the simple breakdown.

1. General Concepts

Defines terminology and the model for securing industrial environments.

2. Policies and Procedures

Covers management commitment, responsibilities, change control, patching, and incident response.

3. System Security Requirements

Defines how entire systems should be secured, including network zones and conduits.

4. Component Security Requirements

Defines security expectations for individual devices such as PLCs, drives, sensors and controllers.

Plant managers do not need to memorize the parts. What matters is understanding the structure and applying it in phases.

What Are Zones and Conduits?

This is the core idea of IEC 62443 - zones are groups of assets with similar security needs.

- Office network

- Production control network

- Safety system

- CNC cell

- Robot cell

- Remote access area

Conduits are the controlled paths that connect zones. They define how traffic flows and how it is protected. Zones isolate problems. Conduits control communication. This stops a breach in one machine from spreading across the plant.

What Are Security Levels (SL1 to SL4)?

IEC 62443 defines four levels of protection.

- SL1: protects against accidental misuse

- SL2: protects against simple cyber attacks

- SL3: protects against skilled attackers with resources

- SL4: protects against advanced and targeted attacks

Most production plants aim for SL2 or SL3 in critical zones.

What Does IEC 62443 Require Plants to Do?

Here is a simplified requirement list that fits any CNC or manufacturing environment:

-

Inventory all OT assets

Machines, PLCs, HMIs, robots, drives, sensors. -

Segment the network into zones

Keep production isolated from office IT. -

Control remote access

Vendors and technicians must use secure methods. -

Manage patches and updates

Track what is updated, what is not, and why. -

Monitor machines and networks

Detect unusual activity or unauthorized changes. -

Enforce user roles and passwords

Operators, technicians and engineers should have different access levels. -

Prepare an incident response plan

Know who to call, what to shut down, and what to restore first. -

Train staff

Many OT incidents start with human error.

These steps do not require large budgets. They require discipline.

How Does IEC 62443 Improve Production Reliability?

Plant managers usually ask one thing: does this actually help my output. The answer is yes. IEC 62443 improves reliability by:

- Preventing malware that stops machines

- Reducing unwanted downtime

- Protecting recipes, NC programs and parameters

- Blocking unauthorized changes to PLC logic

- Keeping critical systems stable during incidents

- Allowing safe and controlled vendor access

Cybersecurity is not an IT project. It is a production continuity project.

How Do You Start Implementing IEC 62443?

Step 1. Assess your current risk

Identify the most critical machines and the biggest vulnerabilities.

CNCs, molding machines, packaging lines and robots are always the priority.

Step 2. Create zones

Separate production, engineering, office networks, and vendor access.

Step 3. Secure remote access

Use VPN, MFA and session logs. Remove open ports.

Step 4. Set up password roles

Operators should not have engineering access.

Step 5. Enable monitoring

Use any monitoring tool, even basic, to detect unusual traffic or PLC logic changes.

Step 6. Build procedures

Change control, patching, documentation and staff training. This is enough to reach IEC 62443 maturity faster than most plants.

Frequently Asked Questions

Is IEC 62443 required by law?

Usually no, but many OEMs, medical and automotive customers require it in supplier audits.

Do small factories need IEC 62443?

Yes. Small plants are targeted more often because they have fewer protections.

How long does implementation take?

Basic zoning and access control can be done in weeks. Full adoption can take months depending on system complexity.

Is IEC 62443 only for IT teams?

No. It is mostly for OT teams, operators, maintenance, and controls engineers.

Final Summary

IEC 62443 is the most important cybersecurity standard for modern manufacturing. It protects production systems, supports uptime and keeps plants safe. Plant managers do not need to understand every technical detail. They need to apply the core principles: know your assets, segment your networks, control access, monitor activity, and train people.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?