No more manufacturing downtimes

Get started with your projectEmerging Trends in Manufacturing for 2025

Rapid advancements in technology are revolutionizing how businesses operate, innovate, and compete. From the integration of cutting-edge smart technologies to a growing emphasis on environmental sustainability, manufacturers are navigating a landscape that demands agility and foresight. At the same time, the industry faces new challenges that require strategic thinking and innovative solutions. By understanding and embracing these trends, businesses can secure a strong foothold in a dynamic global market. Below, we delve into the most critical developments shaping the future of manufacturing.

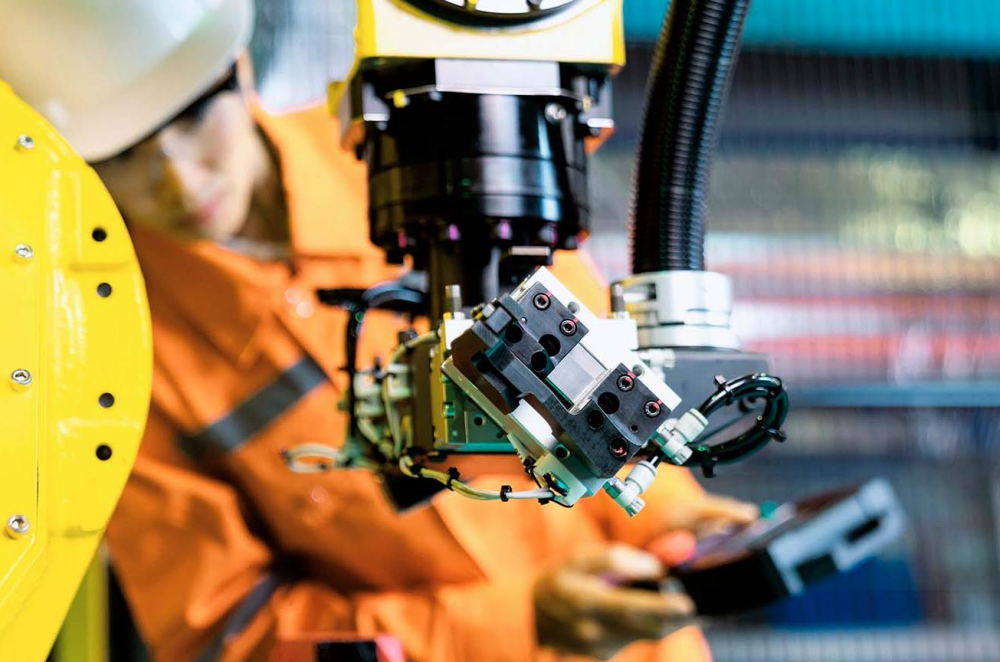

Embracing Industry 4.0

Industry 4.0 continues to lead the charge in revolutionizing manufacturing. It represents a seamless integration of digital technologies with traditional manufacturing processes, creating smart factories that operate with unprecedented efficiency and adaptability. Key aspects include:

- Enhanced Connectivity: Real-time communication between machines, systems, and stakeholders to improve coordination and reduce downtime.

- Automation and Robotics: Deploying advanced robotics to optimize workflows and reduce costs.

- Data-Driven Insights: Harnessing big data to predict trends, optimize processes, and make informed decisions.

By adopting Industry 4.0 principles, manufacturers can achieve smarter, more adaptive operations capable of responding to market demands swiftly and effectively. This shift is not just about technology; it’s about rethinking how businesses operate in a hyper-connected world.

Advanced Manufacturing Techniques

Advanced manufacturing methods are pushing the boundaries of what is possible in production. These innovative approaches are reshaping how products are designed, developed, and delivered. Key technologies include:

- Additive Manufacturing (3D Printing): Enabling customized and complex designs with unprecedented speed and cost efficiency.

- Robotics Integration: Enhancing precision, safety, and productivity on the production floor.

- AI-Driven Design: Using computational tools to create optimized products and processes tailored to specific needs.

The agility provided by these techniques enables businesses to keep pace with evolving consumer demands while fostering innovation. Advanced manufacturing is not just about efficiency; it’s about unlocking new possibilities and markets.

Integration of Smart Manufacturing Technologies

Smart manufacturing technologies are redefining how manufacturers operate, enabling higher levels of efficiency, precision, and innovation. These technologies are the backbone of modern manufacturing, driven by the capabilities of Artificial Intelligence, the Internet of Things, and Machine Learning. Key advancements include:

- Data-based Insights: Identifying potential issues before they disrupt production to ensure uninterrupted workflows.

- Real-Time Monitoring: Providing instant, actionable insights into operations, enabling quick and informed decision-making.

- Automated Processes: Streamlining repetitive tasks to reduce human error while maintaining high accuracy.

The adoption of these technologies is no longer optional - it is a strategic imperative for staying competitive in the modern manufacturing landscape. Businesses that invest in smart manufacturing will gain a significant edge, driving efficiency, cost savings, and innovation.

Cybersecurity in Manufacturing

As manufacturing becomes more digitized, cybersecurity has emerged as a critical concern. Protecting digital assets, intellectual property, and operational systems is vital in an era of increasing cyber threats. Key measures include:

- Robust Security Protocols: Implementing comprehensive strategies to safeguard sensitive information.

- Employee Training: Building awareness of cybersecurity practices across the workforce to prevent breaches.

- System Monitoring: Detecting and responding to potential vulnerabilities in real time to maintain operational continuity.

Investing in cybersecurity ensures not only the safety of operations but also the trust of partners and customers in an interconnected manufacturing ecosystem. A secure manufacturing environment is foundational to sustained growth and innovation.

Focus on Sustainable Manufacturing

The increasing emphasis on environmental sustainability is reshaping manufacturing practices. Businesses are committing to strategies that reduce their environmental footprint while enhancing operational efficiency. Sustainability is not just about compliance; it’s about creating value for customers, stakeholders, and the planet. Key initiatives include:

- Carbon Emission Reduction: Investing in cleaner technologies and energy-efficient equipment to align with global climate goals.

- Circular Economy Practices: Minimizing waste through innovative recycling, reusing materials, and designing for longevity.

- Renewable Energy Utilization: Powering operations with sustainable energy sources to reduce dependence on fossil fuels.

Sustainable manufacturing is no longer a niche trend; it is central to long-term business strategy. Companies that embrace green practices not only meet regulatory requirements but also resonate with eco-conscious consumers and investors.

Looking Ahead in 2025

The manufacturing landscape in 2025 promises to be more connected, innovative, and sustainable than ever before. Businesses embracing these emerging trends will position themselves for success in a competitive and rapidly evolving market. By focusing on smart manufacturing technologies, sustainable practices, Industry 4.0, advanced techniques, and robust cybersecurity, manufacturers can thrive in the new era. Success will depend on adaptability, continuous improvement, and a proactive approach to leveraging opportunities and overcoming challenges.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Sources:

- World Economic Forum, and Boston Consulting Group. Harnessing the AI Revolution in Industrial Operations: A Guidebook. World Economic Forum, October 2023,

- Viking Analytics. "Preventive vs. Predictive Maintenance: Which Is More Effective?" LinkedIn

- Olavsrud, Thor. "Digital Twins: 4 Success Stories." CIO

- Coykendall, John, et al. "2025 Manufacturing Industry Outlook." Deloitte Insights

- Bureau of Labor Statistics, U.S. Department of Labor. “U.S. manufacturing output, hours worked, and productivity recover from COVID-19.” The Economics Daily

- Boak, Josh. "US to Provide $325 Million for New Michigan Semiconductor Factory." AP News

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.