MAZAK CNCs - Top 3 CNC for Beginners and Pros

Yamazaki Mazak, established in 1919, is a leading global manufacturer of advanced CNC (Computer Numerical Control) machines. Renowned for their innovation and precision, Mazak offers a diverse range of machines tailored to various manufacturing needs.

Top 3 Mazak CNC Machines for Beginners

Selecting an entry-level CNC machine is crucial for newcomers to ensure ease of use without compromising on quality.

Mazak Quick Turn 200

Mazak VC-Ez 20

Mazak VCN-430A

-

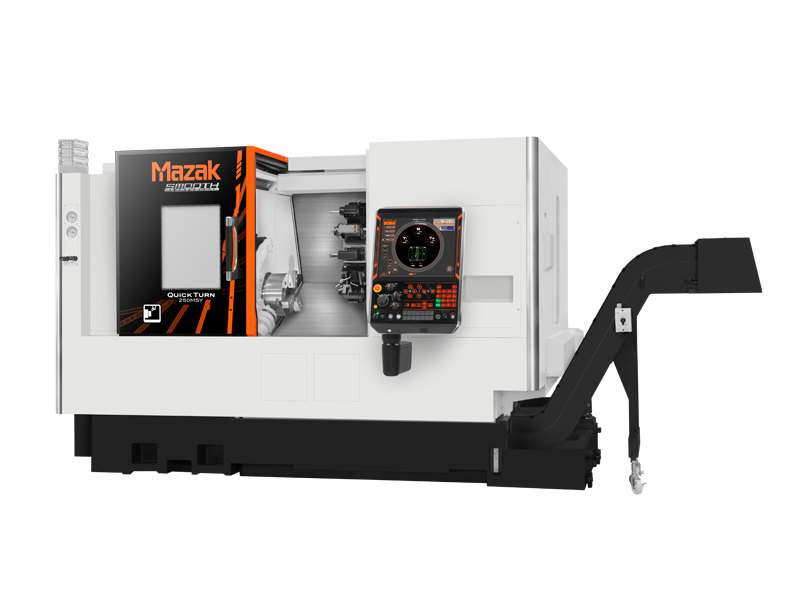

Mazak Quick Turn 200

-

Description: Part of Mazak's renowned Quick Turn series, the Quick Turn 200 is designed for high-performance turning operations.

-

Features: Offers a main spindle speed of up to 5,000 RPM, a maximum machining diameter of 14.75 inches, and a 12-tool turret. Its user-friendly MAZATROL SmoothG CNC system simplifies programming and operation.

-

Why Suitable for Beginners: Combines simplicity with efficiency, making it ideal for those new to CNC turning. Its intuitive controls and reliable performance provide a solid foundation for learning and production.

-

Applications: Suitable for producing a variety of components, including shafts, bushings, and other cylindrical parts.

-

-

Mazak VC-Ez 20

-

Description: An entry-level vertical machining center offering high performance and ease of use.

-

Features: Equipped with a 12,000 RPM spindle, a 20-tool magazine, and a compact footprint. The MAZATROL SmoothEz control provides straightforward programming, making it accessible for beginners.

-

Why Suitable for Beginners: Designed with simplicity in mind, it offers essential features without overwhelming complexity, allowing new users to gain confidence and proficiency.

-

Applications: Suitable for machining small to medium-sized components across various industries.

-

-

Mazak VCN-430A

-

Description: A vertical machining center that balances performance and user-friendliness.

-

Features: Features a 12,000 RPM spindle, a 30-tool magazine, and a robust construction. The MAZATROL SmoothG CNC system enhances its adaptability across different operations.

-

Why Suitable for Beginners: Offers a combination of advanced features and intuitive controls, making it suitable for those transitioning from manual to CNC machining.

-

Applications: Ideal for producing parts ranging from simple brackets to complex molds and dies.

-

Top 3 Advanced Mazak CNC Machines

For manufacturers seeking cutting-edge technology and multifunctionality, advanced machines offer unparalleled capabilities.

Mazak INTEGREX i-400ST

Mazak HQR-200/3 NEO

Mazak VORTEX i-V

-

Mazak INTEGREX i-400ST

-

Description: A multi-tasking machine that seamlessly integrates turning and milling operations.

-

Features: Equipped with twin spindles and twin turrets, enabling simultaneous multi-tasking operations. This design reduces cycle times and increases throughput by allowing seamless transitions between turning and milling operations.

-

Why It's Advanced: The twin-spindle, twin-turret configuration allows for complex machining tasks to be completed in a single setup, reducing production time and increasing accuracy.

-

Applications: Ideal for complex components in aerospace, automotive, and medical industries, such as turbine blades and orthopedic implants.

-

-

Mazak HQR-200/3 NEO

-

Description: A high-capacity turning center featuring three turrets and two spindles, designed to enhance productivity and environmental performance.

-

Features: The addition of a third turret reduces cycle times by approximately 25% compared to two-turret configurations. It supports complex part production in a single setup and integrates easily with automation systems.

-

Why It's Advanced: The triple-turret design and enhanced automation features allow for simultaneous machining operations, significantly boosting productivity and precision.

-

Applications: Suited for medium to large batch production in industries like aerospace, automotive, and general subcontracting.

-

-

Mazak VORTEX i-V

-

Description: A 5-axis machining center with a vertical body and a tilting B-axis head, capable of handling large aerospace or automotive parts.

-

Features: Pallet sizes of approximately 630 mm by 630 mm or 800 mm by 800 mm, using a CAT No.50 spindle at 10,000 rpm. It accommodates maximum part diameters approaching 1,700 mm and heights up to 1,600 mm.

-

Why It's Advanced: The tilt spindle design allows for complex angle machining with high stability, making it suitable for heavy and bulky parts.

-

Applications: Ideal for large aerospace or automotive components, such as structural parts and large castings.

-

Top 3 Versatile Mazak CNC Machines

Versatile machines provide flexibility to handle a wide range of machining tasks, adapting to various production requirements.

Mazak VARIAXIS C-600

Mazak VTC-530C

OKUMA MB-46VA

-

Mazak VARIAXIS C-600

-

Description: A compact, high-accuracy simultaneous 5-axis vertical machining center.

-

Features: Accommodates workpieces up to Ø730 mm x H450 mm and 500 kg. Offers rapid traverse rates of 42 m/min in the X-, Y-, and Z-axes, with a chip-to-chip time of 4.5 seconds. Multiple spindle options are available, ranging from 12,000 rpm to 20,000 rpm.

-

Why It's Versatile: Suitable for industries such as aerospace and automotive, capable of handling a wide range of materials and complex geometries.

-

Applications: Ideal for producing intricate components like turbine blades and automotive parts.

-

-

Mazak VTC-530C

-

Description: A compact vertical machining center designed for flexibility in various metal-cutting applications.

-

Features: Equipped with a 12,000 rpm, 18.5 kW spindle, direct drive ballscrews, and roller linear guides. Offers rapid feed rates up to 42 m/min in the X-, Y-, and Z-axes. Includes an Automatic Tool Changer with a 30-tool capacity, supporting tools up to 350 mm in length and 8 kg in weight.

-

Why It's Versatile: Accommodates larger workpieces with an X-axis stroke of 1,740 mm. An optional center partition allows simultaneous machining and pendulum loading, enhancing productivity.

-

Applications: Suitable for sectors including oil and gas, aerospace, automotive, and medical industries.

-

-

Mazak FJV 5 Face-100/160

-

Description: A 3-axis CNC vertical machining center capable of machining workpiece top and side surfaces in a single setup.

-

Features: Offers X, Y, and Z travels of 4,200 mm, 2,450 mm, and 660 mm respectively. Equipped with a 10,000 rpm spindle and a 60-tool magazine. The angle head with automatic tool changer enables continuous machining of four side surfaces of a workpiece.

-

Why It's Versatile: Designed for large workpieces requiring multi-face machining, reducing in-process time and increasing efficiency.

-

Applications: Ideal for industries requiring precision machining of large components, such as aerospace and heavy equipment manufacturing

-

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.