Practical Guide to IIoT in Smart Manufacturing: Devices, Use Cases & Popular Models

1. Condition Monitoring on CNC Machines

Scenario: A machine shop wants to reduce unplanned downtime of their CNC lathes and mills by monitoring key health parameters.

Devices Used:

| Sensor Type | Model | Vendor | Role |

|---|---|---|---|

| Vibration Sensor | IFM VVB001 | IFM | Tracks bearing health and imbalance |

| Temperature Sensor | Omega RTD-805 | Omega Engineering | Monitors spindle or motor temperature |

| Current Sensor | Fluke iFlex 3000 | Fluke | Detects abnormal power draw patterns |

| Gateway | Ewon Flexy 205 | HMS Networks | Aggregates and sends data to cloud/MES |

| Edge PC | Advantech UNO-1372G | Advantech | Runs local analytics and dashboards |

2. Energy Monitoring Across Factory Floor

Scenario: A medium-sized discrete manufacturing plant aims to optimize energy usage to comply with ESG goals and reduce costs.

Devices Used:

| Sensor Type | Model | Vendor | Role |

|---|---|---|---|

| Power Meter | Schneider Electric PM8000 | Schneider Electric | Monitors real-time power quality and consumption |

| Current Transformers | CR Magnetics CR4310 | CR Magnetics | Measures load per machine |

| Gateway | Siemens Simatic IOT2050 | Siemens | Edge device for Modbus-to-MQTT conversion |

| HMI | Red Lion G3 HMI | Red Lion | Displays factory-wide energy dashboard |

3. Visual Quality Inspection in Electronics Assembly

Scenario: An EMS (Electronics Manufacturing Services) provider wants to detect solder defects and missing components inline.

Devices Used:

| Sensor Type | Model | Vendor | Role |

|---|---|---|---|

| Industrial Camera | Cognex In-Sight 2800 | Cognex | Captures and analyzes high-speed images inline |

| AI Edge Platform | NVIDIA Jetson Xavier NX | NVIDIA | Runs deep learning models for visual defect detection |

| Lighting System | Metaphase Bright Field Ring Light | Metaphase | Ensures image clarity |

| Communication | PoE Switch + MQTT Broker (Mosquitto) | — | Sends flagged defects to MES |

4. Predictive Maintenance in Industrial Pumps

Scenario: A chemical plant uses predictive maintenance to reduce pump failures in critical liquid transfer systems.

Devices Used:

| Sensor Type | Model | Vendor | Role |

|---|---|---|---|

| Vibration + Temperature Sensor | SKF IMx-8 | SKF | Multi-channel condition monitoring |

| Pressure Sensor | WIKA A-10 | WIKA | Monitors pressure stability |

| Edge Gateway | Moxa UC-8112 | Moxa | Performs edge filtering and alerts |

| Cloud Platform | AWS IoT Core | Amazon | Centralized data collection and predictive modeling |

5. Real-Time Tracking in Smart Assembly Line

Scenario: A Tier-1 automotive supplier needs real-time traceability of part movement and assembly operations.

Devices Used:

| Device Type | Model | Vendor | Role |

|---|---|---|---|

| RFID Reader | Turck TNLR-Q80 | Turck | Tracks part location at each assembly stage |

| Barcode Scanner | Keyence SR-2000 | Keyence | Scans serials for WIP tracking |

| Proximity Sensor | Pepperl+Fuchs NJ2-V3-N | Pepperl+Fuchs | Confirms component placement in jigs |

| PLC | Rockwell CompactLogix 5380 | Rockwell Automation | Controls line logic, syncs with MES |

| Connectivity | EtherNet/IP with OPC-UA bridge | — | Interfaces with ERP and dashboards |

6. Remote Monitoring of Offshore or Hazardous Sites

Scenario: A mining equipment provider monitors machine performance at remote locations with limited connectivity.

Devices Used:

| Sensor Type | Model | Vendor | Role |

|---|---|---|---|

| Multi-sensor Node | Banner QM42VT1 | Banner Engineering | Monitors vibration, temp, runtime |

| Cellular Gateway | Digi IX20 | Digi International | Secure LTE/4G remote data transmission |

| Battery Power Pack | ABB Remote Battery Kit | ABB | Supports off-grid deployment |

| Cloud Dashboard | ThingWorx, Azure IoT Hub | PTC, Microsoft | Provides alerting and remote diagnostics |

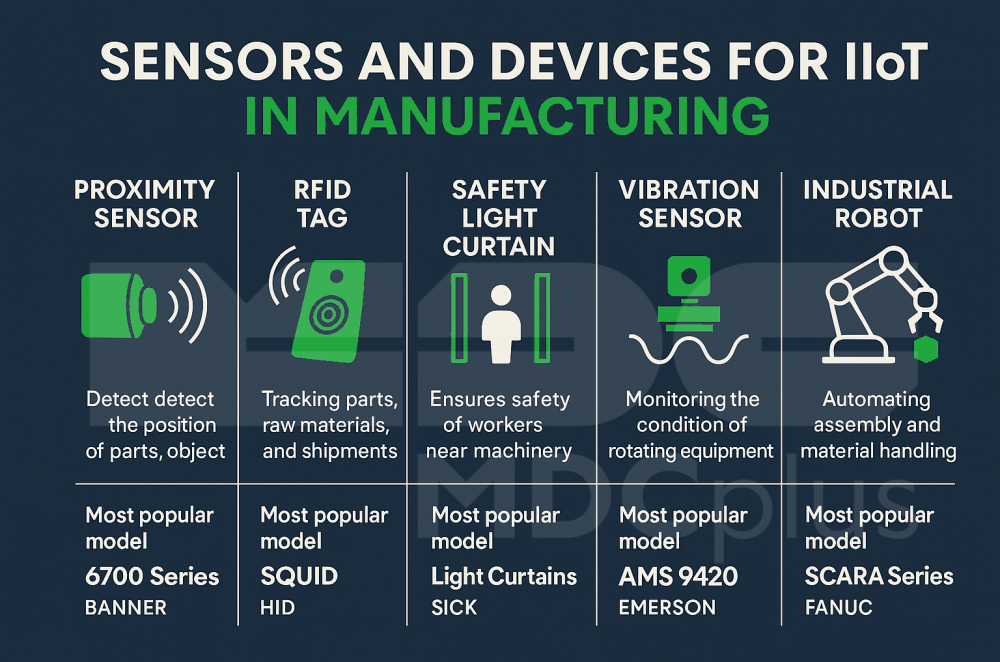

Bonus: Most Popular Models in U.S. Manufacturing (2024–2025 Trends)

| Purpose | Popular Model | Brand | Reason for Popularity |

|---|---|---|---|

| Edge Gateway | Ewon Flexy 205 | HMS Networks | Easy PLC integration, secure VPN |

| Vibration Sensor | IFM VVB Series | IFM | Robust, plug-and-play for harsh conditions |

| Vision System | Cognex In-Sight 2800 | Cognex | No-code AI, industry-trusted |

| PLC | Rockwell CompactLogix 5380 | Rockwell | U.S. standard for control systems |

| Smart HMI | Siemens Comfort Panel TP900 | Siemens | Touchscreen + WinCC integration |

| Energy Meter | Schneider PM8000 Series | Schneider Electric | Cybersecure and scalable |

| Edge Compute | Advantech UNO-1372G | Advantech | Industrial-grade, compact IPC |

The U.S. manufacturing ecosystem demands proven, interoperable, and secure IIoT devices. Whether you're optimizing energy, enabling predictive maintenance, or deploying advanced vision AI, the use case should drive the tech choice—not the other way around.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.