No more manufacturing downtimes

Get started with your projectReal-Time Production Monitoring System Explained

Keeping up with the demands of modern manufacturing requires precision, efficiency, and a commitment to innovative solutions. Learn more about real-time production monitoring systems with MDCplus team.

Maintaining competitiveness in modern manufacturing requires more than traditional monitoring methods. Real-time production monitoring systems have become indispensable, offering manufacturers immediate insights into their operations. By gathering and analyzing production data continuously, these systems enable quick responses to issues, ensuring efficiency and consistent product quality. Incorporating advanced production monitoring software further enhances the ability to manage and optimize processes effectively.

Key Features of Real-Time Production Monitoring Systems

Understanding the essential attributes of real-time production monitoring systems provides clarity on how these tools transform manufacturing operations. Each feature addresses specific challenges in production processes, ensuring seamless integration and enhanced performance across the board.

-

Real-Time Data Collection and Visualization

-

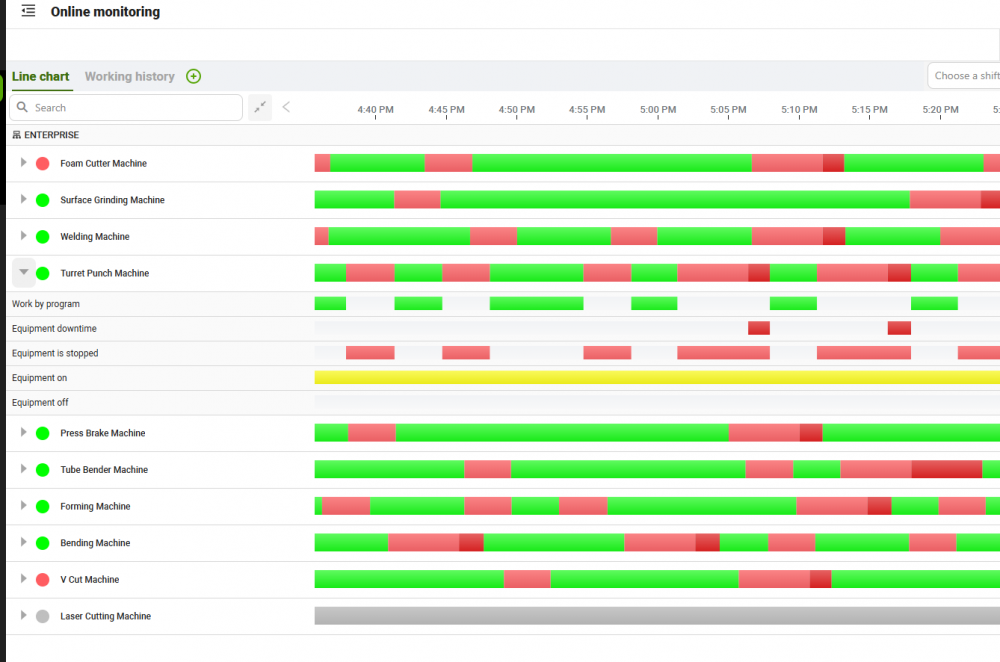

These systems collect data directly from machinery and display it on intuitive dashboards, enabling operators to monitor performance metrics as they happen. Real-time data visualization ensures a clear and immediate understanding of production conditions.

-

-

Automated Downtime Tracking

-

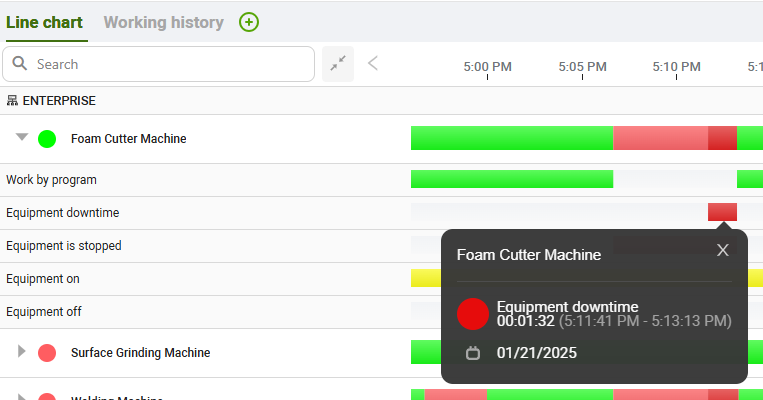

By logging downtime events automatically, manufacturers can detect patterns and root causes, facilitating targeted measures to reduce interruptions. Downtime tracking plays a pivotal role in maintaining seamless operations and minimizing inefficiencies.

-

-

Performance Analytics and Reporting

-

Comprehensive analytics provide detailed reports on critical performance indicators, such as Overall Equipment Effectiveness (OEE), supporting informed decision-making. Advanced production monitoring software often integrates these features seamlessly.

-

-

User-Friendly Interfaces

-

Designed for accessibility, these systems minimize training requirements, ensuring operators can use the tools effectively without disrupting their primary tasks.

-

Benefits of Implementing Real-Time Monitoring

Implementing real-time monitoring systems offers transformative advantages for manufacturing processes. By leveraging these systems, organizations can address key operational challenges, drive productivity, and achieve consistent results. The following benefits illustrate the impact of adopting these tools:

-

Increased Operational Efficiency

-

Real-time insights allow manufacturers to make proactive decisions, reducing inefficiencies and maximizing resource utilization. Operational efficiency is a core outcome of real-time production monitoring systems.

-

-

Minimized Downtime and Maintenance Costs

-

Continuous monitoring identifies potential issues before they escalate, reducing unplanned downtime and repair expenses. Effective downtime tracking ensures that costly disruptions are minimized.

-

-

Enhanced Product Quality

-

Detailed monitoring ensures consistent quality by providing actionable feedback on production processes. Real-time data visualization highlights areas for improvement in real time.

-

-

Better Decision-Making

-

Actionable insights from these systems support management in making strategic, data-backed decisions that promote growth and productivity.

-

Using MDCplus as Real-Time Production Monitoring

MDCplus provides a highly effective real-time production monitoring system designed to streamline manufacturing processes. With capabilities like real-time data collection, automated downtime tracking, and comprehensive analytics, MDCplus enables manufacturers to achieve outstanding operational efficiency and product quality. Combining intuitive interfaces and seamless integration, MDCplus stands out as a trusted choice for businesses looking to enhance their production performance through reliable production monitoring software and innovative solutions.

Challenges and considerations to be taken

Real-time production monitoring systems, while highly beneficial, come with their own set of challenges. Recognizing these considerations helps businesses prepare for a smooth implementation and ensures long-term success. Below are some key aspects to keep in mind:

-

System Integration: MDCplus ensures a smooth integration process by providing robust compatibility with existing systems and offering expert support during implementation. This approach reduces complexity and ensures a seamless operation from the start.

-

Upfront Investment: while initial costs for technology and infrastructure can be a consideration, MDCplus delivers exceptional long-term value. Its cost-effective solutions are designed to maximize ROI through improved efficiency and reduced downtime.

-

Staff Training: MDCplus prioritizes comprehensive training programs tailored to the specific needs of each organization. These programs ensure employees are well-equipped to fully utilize the system, optimizing its effectiveness and empowering teams to achieve operational excellence.

Implementing a real-time production monitoring system can revolutionize manufacturing operations, delivering improved efficiency, quality, and profitability. These systems, coupled with advanced production monitoring software, provide comprehensive tools to streamline operations and address challenges effectively. Businesses should evaluate their needs carefully and choose solutions that align with their operational objectives, ensuring a sustainable competitive edge.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?