Make your machining more efficient

Get started with MDCplusOKUMA CNC - Top 3 Best Machines For Manufacturers

OKUMA Corporation, established in 1898, is renowned for its CNC machine tools, including lathes, machining centers, grinders, and multitasking machines. The company's "Single Source" philosophy ensures all components are designed and built in-house, enhancing quality and innovation. To identify the top 3 machines in each category, we analyzed OKUMA's product catalog, website, and industry discussions, focusing on features like ease of use, advanced technology, and versatility.

Top 3 Machines for Beginners

Beginner machines are crucial for small shops or new CNC users, offering simplicity and affordability. The following models were selected based on their entry-level design and suitability for basic operations:

OKUMA GENOS L250II

OKUMA GENOS L400II

OKUMA MB-46VA

- GENOS L250II (Lathe):

- Description: Part of OKUMA's GENOS series, this lathe is marketed as an affordable, entry-level option, ideal for small to medium-sized shops.

- Features: Compact design, basic control system, standard spindle speeds, and travel ranges up to 18.5" in Z-axis, with chuck sizes of 6" or 8". It occupies minimal floor space, around 30 square feet, enhancing accessibility.

- Why Suitable for Beginners: Its simplicity and lower cost make it perfect for those new to CNC lathe operations, providing a straightforward introduction to turning. It’s noted for stability, rigidity, and accuracy, built on a one-piece cast iron base with hand-scraped mounting surfaces (Okuma | EMEC Machine Tools Inc.).

- Applications: Ideal for basic turning tasks, such as creating cylindrical parts, suitable for educational settings or small-scale production.

- GENOS L400II (Lathe):

- Description: Another entry-level lathe from the GENOS series, offering larger capacity than L250II, suitable for slightly more demanding tasks.

- Features: Features a 10" chuck and Z-axis travel of 43.31", built on a one-piece cast iron base with horizontal way system and hand-scraped mounting surfaces, ensuring stability and accuracy.

- Why Suitable for Beginners: It provides a step up in capacity, allowing beginners to handle more complex turning tasks as they gain experience, without overwhelming them with advanced features. Its affordability and ease of use make it accessible (Arizona CNC Equipment | Okuma).

- Applications: Suitable for medium-sized turning operations, such as shafts or larger cylindrical components, ideal for expanding small shops.

- MB-46VA (Vertical Machining Center):

- Description: A standard vertical machining center, part of OKUMA's MB-V series, known for efficiency and high speed.

- Features: Table size around 1000 x 460 mm, travel distances of 762 mm in X, 460 mm in Y and Z, spindle speed of 8000 rpm, and a 20-position automatic tool changer. It incorporates OKUMA's Thermo-Friendly Concept for dimensional stability (CNC Machine | Vertical Machining Center | VMC | MB-46V).

- Why Suitable for Beginners: Its basic tool changer and standard spindle speeds make it a good starting point for milling operations, offering essential functionalities without complexity. The ergonomic front-access design requires minimal floor space, enhancing usability for new users.

- Applications: Ideal for general milling tasks, such as creating flat surfaces or drilling, suitable for small-scale manufacturing or training environments.

Top 3 Most Advanced Machines

Advanced machines are characterized by the latest technology, high precision, and complex capabilities, catering to high-end manufacturing needs. The following models were selected based on their advanced features and suitability for complex, precision-driven applications:

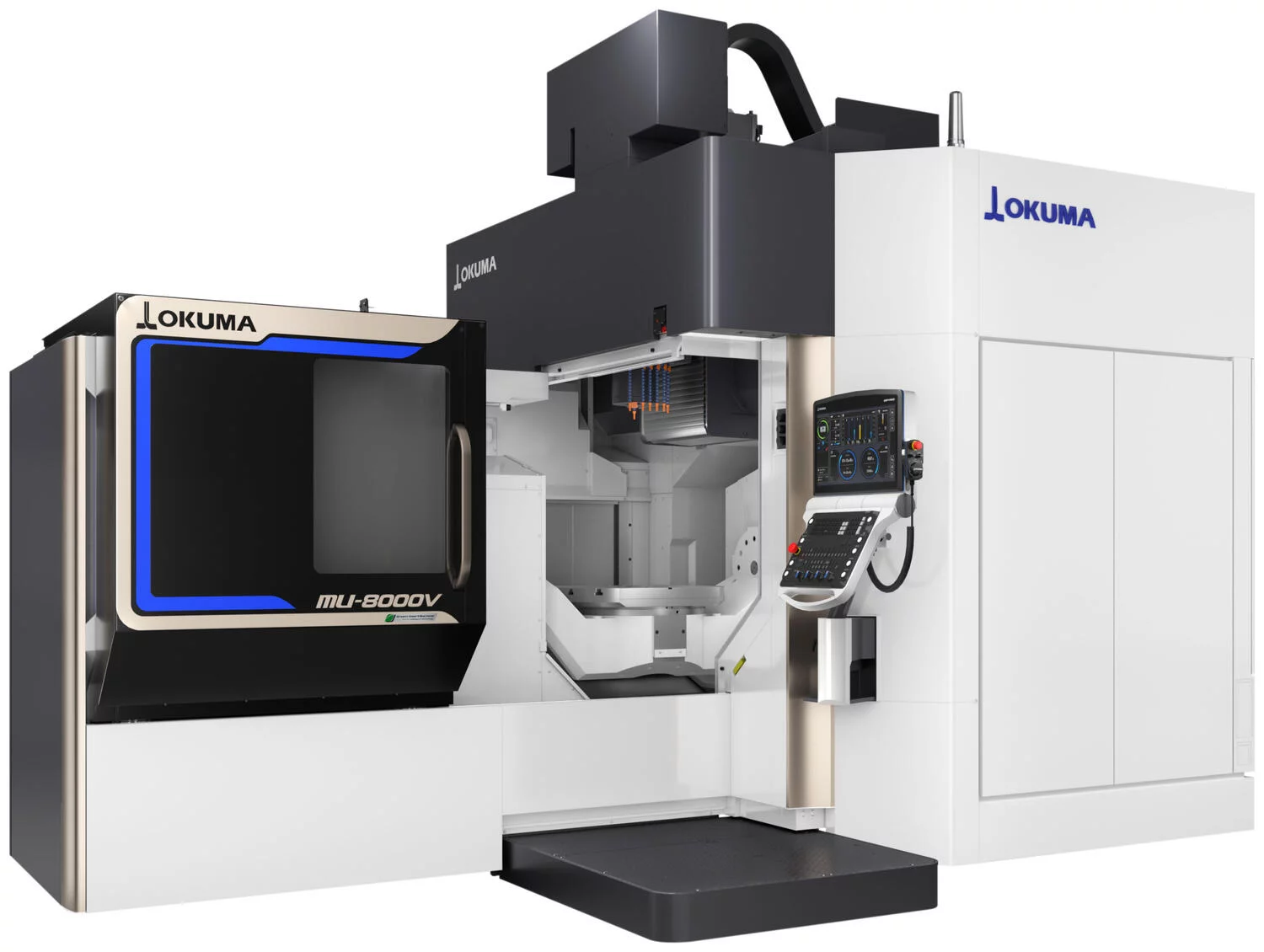

OKUMA MU-8000V

OKUMA MCR-C

OKUMA MU-6300V

- MU-8000V LASER EX (Super Multitasking Machine):

- Description: A top-of-the-line super multitasking machine, part of OKUMA's advanced lineup, capable of both turning and milling with integrated laser technology.

- Features: Includes laser tool measurement for high precision, high-speed spindle, advanced control system, and large work envelope, suitable for complex part manufacturing. It’s designed for applications requiring tight tolerances and intricate designs, with capabilities for 5-axis machining (Double Column Machining Centers | DCMC CNC Machine | Okuma).

- Why It's Advanced: Its integration of laser technology and multitasking capabilities makes it ideal for industries like aerospace and medical, where precision and complexity are paramount.

- Applications: Used for manufacturing complex, high-precision parts, such as turbine blades or medical implants, requiring both turning and milling in one setup.

- MCR-C (Double-Column Machining Center):

- Description: A robust double-column machining center, known for stability and precision, suitable for large parts and heavy-duty machining.

- Features: Large table size (up to 3000 x 12000 mm in some configurations), high spindle power (60 hp, 4000 RPM), and advanced control systems, with thermal stability for consistent accuracy. It supports 5-axis cutting and has an auto tool changer with 50 positions (OKUMA MCR-C Gantry Machining Centers | MachineTools.com).

- Why It's Advanced: Its ability to handle large, heavy parts with high precision makes it a choice for demanding applications, ensuring efficiency and accuracy in heavy industries.

- Applications: Ideal for machining large components, such as aircraft parts or heavy industrial molds, requiring high power and stability.

- MU-6300V LASER EX (Super Multitasking Machine):

- Description: Another advanced super multitasking machine, offering similar capabilities to MU-8000V but with potentially different specifications.

- Features: High-speed spindle, laser tool measurement, advanced control system, and multitasking capabilities for both turning and milling, with a focus on high-efficiency, high-productivity 5-axis machining (Milling, double column & 5-axis-machines | OKUMA Europe GmbH).

- Why It's Advanced: It provides a balance between the capabilities of MU-8000V and more entry-level machines, suitable for a wide range of advanced manufacturing needs, with enhanced productivity.

- Applications: Suitable for medium to large complex parts, such as automotive components or electronic housings, requiring precision and versatility.

Top 3 Most Versatile Machines

Versatile machines are those that can handle a wide range of tasks, often with multiple axes and the ability to perform both turning and milling, offering flexibility for various applications. The following models were selected based on their multitasking capabilities and adaptability:

OKUMA MU-5000V

OKUMA MULTUS U5000

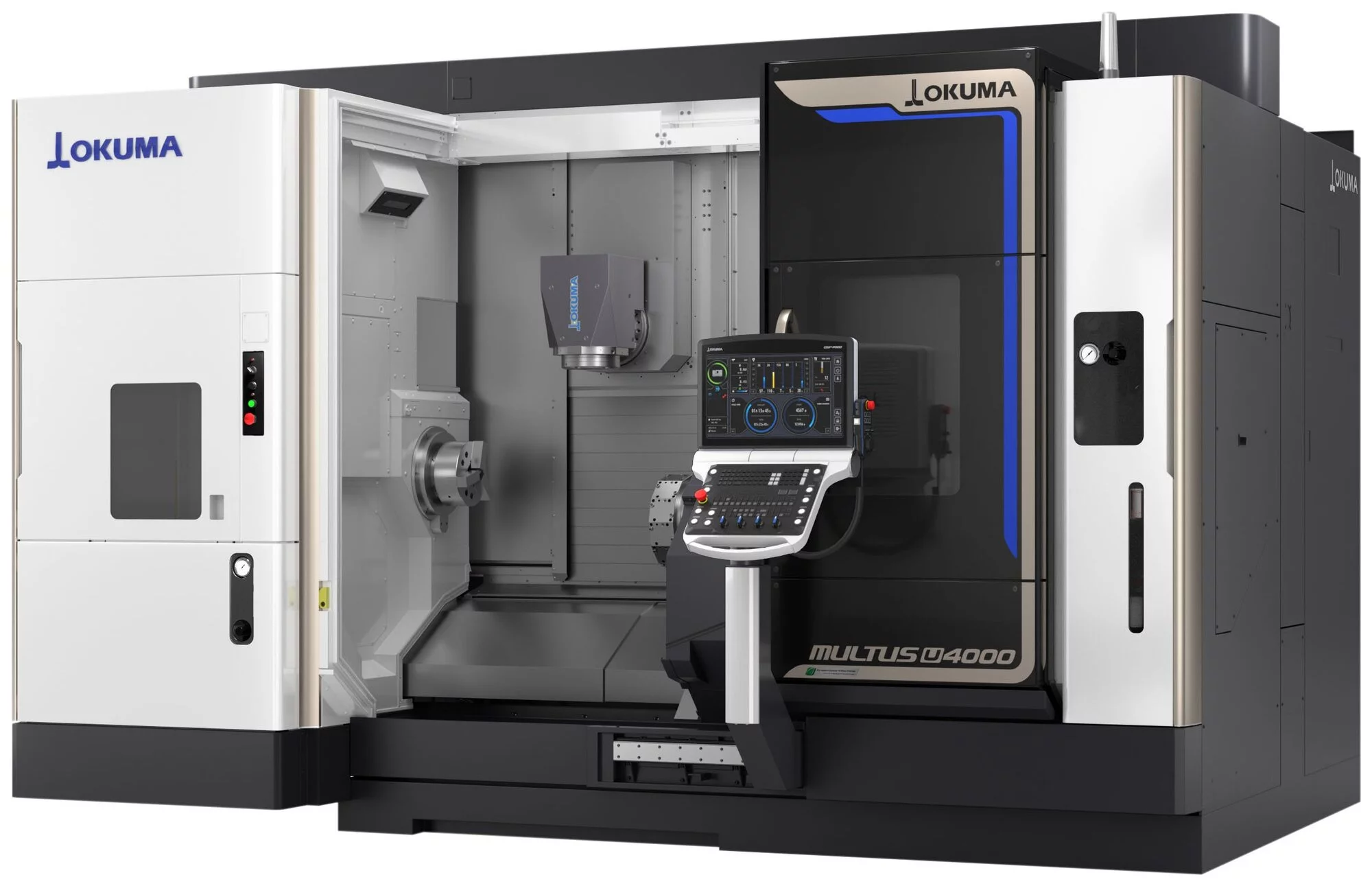

OKUMA MULTUS U4000

- MU-5000V LASER EX (Super Multitasking Machine):

- Description: A super multitasking machine designed for both turning and milling, offering high adaptability.

- Features: Integrated turning and milling capabilities, advanced control system, various tool options, and laser technology for precision, with a focus on reducing setup times (Okuma Advanced Technologies | CNC | Productivity).

- Why It's Versatile: Its ability to handle both turning and milling in one setup makes it highly adaptable for different part geometries, reducing the need for multiple machines and enhancing production efficiency.

- Applications: Ideal for manufacturing parts requiring both cylindrical and milled features, such as shafts with complex milled surfaces, suitable for automotive and aerospace industries.

- MULTUS U5000 (Intelligent Multitasking Machine):

- Description: An intelligent multitasking machine, part of OKUMA's MULTUS series, designed for flexibility in turning and milling operations.

- Features: Combines turning and milling functions, with quick tool changes, high-speed spindles, and advanced control systems, offering a balance between capacity and versatility (Machine Tools Catalogue | OKUMA CORPORATION).

- Why It's Versatile: It offers a wide range of operations in one machine, suitable for various part types, enhancing flexibility in production environments.

- Applications: Used for parts requiring both turning and milling, such as complex automotive components or hydraulic fittings, ideal for medium to high-volume production.

- MULTUS U4000 (Intelligent Multitasking Machine):

- Description: Another model in the MULTUS series, offering similar versatility with potentially different specifications.

- Features: Similar to U5000, it provides comprehensive multitasking capabilities, with possibly different chuck sizes or travel ranges, ensuring adaptability for various tasks (All OKUMA catalogs and technical brochures).

- Why It's Versatile: Its ability to perform multiple operations in one setup ensures flexibility, catering to different size requirements or specific application needs.

- Applications: Suitable for manufacturing parts like valve bodies or turbine components, requiring both turning and milling, ideal for diverse production needs.

Discussion and Implications

The categorization into beginner, advanced, and versatile machines highlights OKUMA's comprehensive product lineup, catering to a wide range of user needs. Beginner machines like GENOS L250II and MB-46VA provide an accessible entry point, while advanced machines like MU-8000V LASER EX and MCR-C address high-precision, complex manufacturing. Versatile machines, such as MU-5000V LASER EX and MULTUS U5000, offer flexibility, reducing setup times and enhancing production efficiency. This analysis, based on current data, ensures users can make informed decisions based on their specific requirements and skill levels.

Table of Machine Comparisons

| Category | Model | Type | Key Features | Primary Applications |

|---|---|---|---|---|

| Beginner | GENOS L250II | Lathe | Compact, basic control, 6"/8" chuck, 18.5" Z-travel | Basic turning, small-scale production |

| Beginner | GENOS L400II | Lathe | 10" chuck, 43.31" Z-travel, cast iron base | Medium turning, expanding shops |

| Beginner | MB-46VA | Vertical Machining Center | 1000x460 mm table, 8000 rpm spindle, 20-tool changer | General milling, training environments |

| Advanced | MU-8000V LASER EX | Super Multitasking Machine | Laser measurement, high-speed spindle, 5-axis | Complex, high-precision parts |

| Advanced | MCR-C | Double-Column Machining Center | Large table, 60 hp, 4000 RPM, thermal stability | Large, heavy parts, aerospace |

| Advanced | MU-6300V LASER EX | Super Multitasking Machine | High-speed, laser tech, advanced control | Medium to large complex parts |

| Versatile | MU-5000V LASER EX | Super Multitasking Machine | Turning & milling, advanced control, laser tech | Parts needing both operations |

| Versatile | MULTUS U5000 | Intelligent Multitasking Machine | Quick tool change, high-speed, turning & milling | Automotive, hydraulic fittings |

| Versatile | MULTUS U4000 | Intelligent Multitasking Machine | Comprehensive multitasking, adaptable specs | Valve bodies, turbine components |

Key Points

- OKUMA offers a wide range of CNC machines, with top picks for beginners, advanced users, and versatile applications.

- For beginners, the GENOS L250II and L400II lathes, and MB-46VA machining center are recommended for their simplicity and affordability.

- The most advanced machines include the MU-8000V LASER EX, MCR-C, and MU-6300V LASER EX, known for high precision and complex capabilities.

- Versatile machines like the MU-5000V LASER EX, MULTUS U5000, and MULTUS U400II are ideal for multiple tasks, including turning and milling.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.