The Most Crucial Parameters to Track in Injection Molding Machines

Injection molding depends on stability. A few seconds too long in cycle time, a pressure curve that wobbles, or a clamp that doesn’t hold tight enough can quietly turn profit into scrap. These small deviations are often invisible until they show up as late deliveries, rising material costs, or exhausted operators trying to keep up.

Automated monitoring doesn’t magically fix these problems—but it shines a light on them, making hidden losses visible and actionable. Let’s look at the parameters that matter most, how they affect the business, and what can be done when they start drifting.

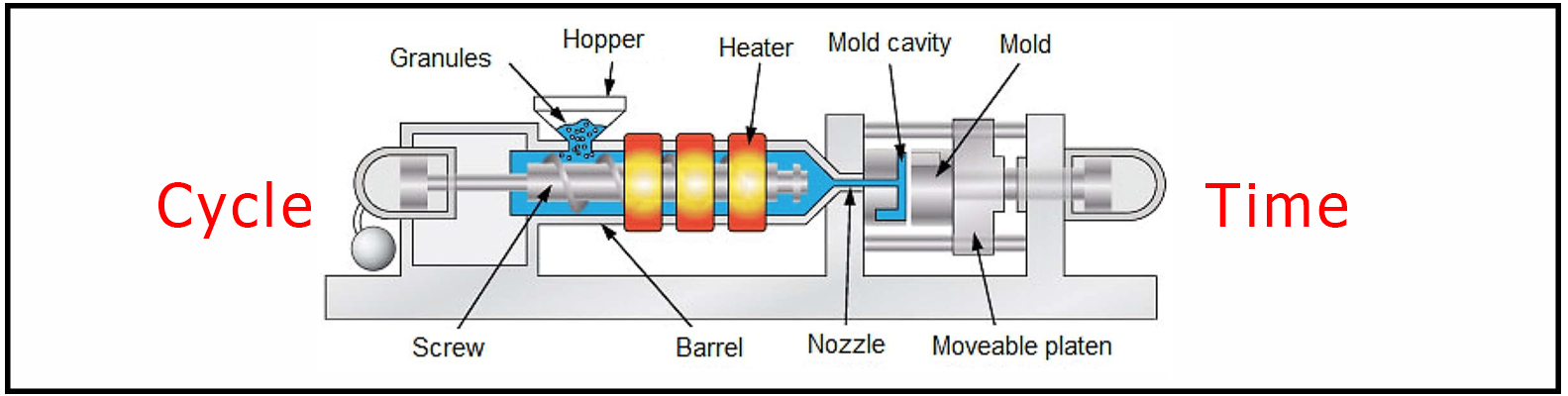

Cycle Time

Cycle time is the pulse of an injection molding machine. On paper, it looks fixed—25 seconds per shot, 30 seconds, whatever the standard is. In practice, it drifts. A second added here or there doesn’t sound like much, but across thousands of cycles it can mean hours of lost production and higher energy use per part. Those delays roll downstream, hitting schedules and customer delivery promises.

When automated tracking shows cycle times creeping up, it’s usually a sign of cooling inefficiency, sluggish machine response, or too much operator intervention. The data points managers straight at the problem instead of leaving them guessing.

Injection and Hold Pressure

Every cavity fill depends on stable pressure. Too low and you get short shots; too high and you’re fighting flash or even damaging molds. Operators may notice defects in finished parts, but by then the material is already wasted and labor time is gone. Pressure swings also stress components like screws and valves, which shortens machine life.

Consistent monitoring highlights when pressure stability degrades, making it clear whether the culprit is material inconsistency, worn components, or poor valve control. Instead of chalking up defects to “bad luck,” teams can correct the process before scrap piles up.

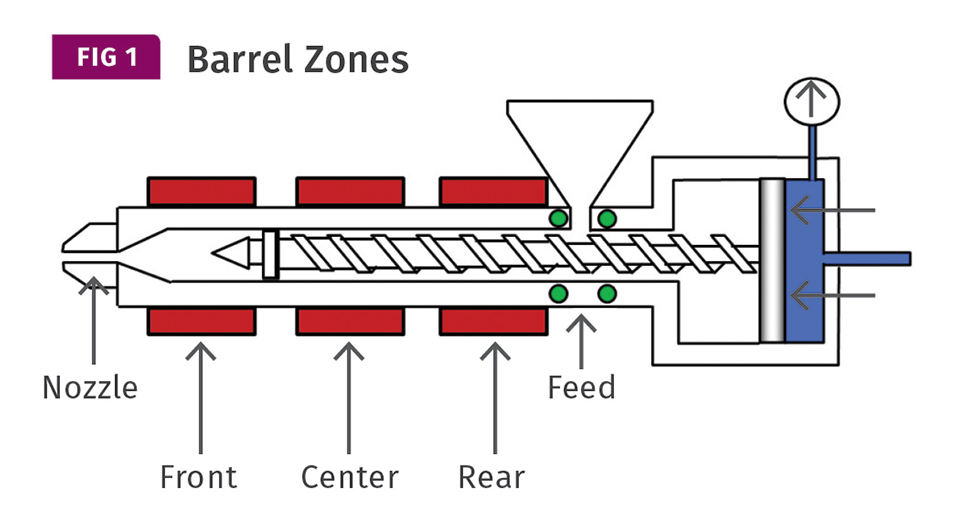

Melt and Barrel Temperatures

Resin is unforgiving when it comes to heat. If barrel zones run cold, the material won’t flow properly; if they overheat, it degrades. In both cases, the cost shows up as scrap and wasted resin, along with operators chasing “mystery defects” that aren’t solved until someone looks at the temperature history.

Tracking melt and zone temperatures in real time removes that guesswork. If heaters are cycling erratically or one zone keeps running out of spec, the data points to failing components or poor insulation. Fixing those early saves resin, energy, and a lot of operator frustration.

Clamping Force

The clamp isn’t glamorous, but it’s critical. If the mold doesn’t stay closed with the right force, flash appears, molds wear faster, and in serious cases, there’s a risk to operator safety. Flash may seem minor, but across thousands of parts it represents significant rework, wasted material, and even mold damage that’s costly to repair.

Trend monitoring shows if clamp force is slipping, often long before it becomes obvious in part quality. That early warning lets maintenance check hydraulics, tie bars, or lubrication schedules before a failure takes a machine out of service.

Cooling Time and Mold Temperature

Cooling is the single longest part of most injection cycles. If it stretches beyond the standard, throughput drops immediately. Uneven or insufficient cooling causes warped or cracked parts that either need rework or go straight to scrap bins. And excessive cooling wastes energy, raising the cost per part without adding value.

When cycle monitoring shows cooling times drifting upward, the cause is often clogged channels, weak flow, or poorly maintained water circuits. Fixing these restores efficiency and improves dimensional stability, without trial-and-error troubleshooting.

Downtime

From the outside, a machine may look like it’s running all day, but small stoppages, extended setups, or waiting for material add up to major hidden downtime. Each minute of idle time is lost output and lost revenue, but without tracking, it’s invisible—operators simply restart and move on.

Breaking downtime into categories—setup, waiting, breakdown—exposes repeat offenders. If mold changes always take 45 minutes instead of 20, or one shift consistently loses time to material shortages, managers know exactly where to focus.

Scrap and Rejects

Finally, not every cycle delivers a usable part. Scrap rates are often higher than reported, especially if operators discard parts without logging them. That hidden waste is expensive: lost resin, wasted labor, and machine hours that could have gone to good parts.

When scrap is tracked per cavity, mold, and shift, patterns appear. A spike tied to unstable pressure, a specific resin lot, or one operator’s setup points to actionable fixes. Instead of vague frustration about “bad quality,” the data connects defects to their root cause.

Injection molding machines rarely fail catastrophically. Instead, they drift—cycles creep longer, pressures fluctuate, temperatures waver, clamps weaken, and scrap quietly grows. Each small deviation chips away at profit until the losses are too big to ignore.

By tracking cycle time, pressures, temperatures, clamping force, cooling, downtime, and scrap, those drifts become visible. The impact is measured not just in numbers but in saved hours, lower material waste, and operators freed from chasing problems they can’t see.

Automated monitoring doesn’t solve every problem on its own—but it makes sure you know where your money, time, and people are being drained, and where to act first.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, we empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

While both involve structured review and analysis, their objectives, scope, and outcomes differ significantly. This article exploring this topic further.