Let you machines speak. Real-time

Give your machines a real-time voice with MDCplus possibilities

Ever wondered, what Industry 4.0 could hold for us in the future? How automation and data collection will help to produce more, become more flexible and meet customer demands? Now it's time. Let us show you how your shop floor can benefit from the gains of the Fourth Industrial Revolution.

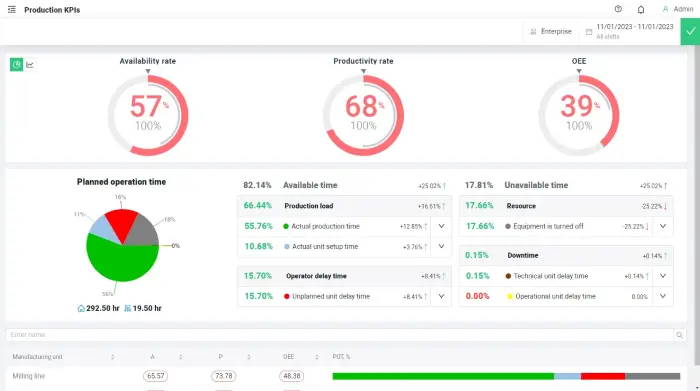

Real-time 360 degree view of all of your machines

- Monitoring the load, state and operating modes of equipment

- Downtime reasons identified and classified

- Operators get help in the performance of production tasks

- Specialists and production departments get automated notifications about accidents and unplanned downtime

- Compiling analytical reports on the operation of equipment and production efficiency

Cloud solution: efficient and flexible, perfect for enterprise

Remote monitoring solution for production equipment anytime and anywhere on the dashboards, timeline, or interactive shop floor layout using a modern Web client.

Data from each machine is transmitted 24/7 and stored on the Microsoft Azure Cloud Server

-

All set up in an hour (fastest project implementation)

-

Higher mobility - convenient access to the information from any device

-

No web or database servers to maintain

-

Low startup costs

-

Automatic software updates included

-

Quick data recovery and loss prevention for all kinds of emergency scenarios

Mobile apps for operators' comfort

- CMP (Collective monitoring panel) is used by multiple users, primarily machine operators

- 1 device per group of machines and operators

- Multiple devices used at the same floor

- IMP (Individual monitoring panel) is a web application designed for interaction between the machine operator and the MDCplus

- Can be installed on the monitoring panel or on a smartphone

- The IMP attached to the machine allows the operator to register only on this machine

- 100+ open protocols

- Cloud and direct connectivity

- No additional hardware needed, just Ethernet cable