- Main

- Blog

Blog

10 April 2025

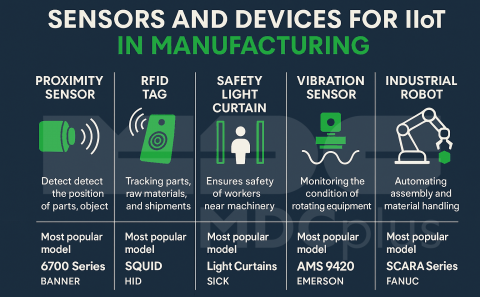

This guide breaks down real-world usage scenarios alongside the most popular IIoT devices and sensors, helping manufacturers make informed choices when designing or scaling their Industry 4.0 projects.

09 April 2025

Digital tools like data-collection systems, real-time monitoring platforms, and MES (Manufacturing Execution Systems) are becoming essential across industries—from automotive to aerospace. But when your software is being used in defense-related manufacturing, there's a regulatory framework you can't afford to ignore: ITAR.

08 April 2025

Manufacturing World Nagoya 2025 is poised to be a cornerstone event for the manufacturing sector, particularly in Central Japan, and is anticipated to be a pivotal gathering for industry professionals. This article provides a detailed overview, confirms the dates, and elucidates why it is considered a must-visit, drawing from official sources and event descriptions.

07 April 2025

In modern manufacturing, the integration of Lean principles with data collection and monitoring systems is pivotal for achieving operational excellence. Lean manufacturing, a methodology focused on minimizing waste and maximizing value, provides a strategic foundation that enhances the effectiveness of data-driven technologies. This article explores why a deep understanding of Lean principles is indispensable for those tasked with implementing manufacturing data collection and monitoring systems, offering detailed insights into its multifaceted benefits.

04 April 2025

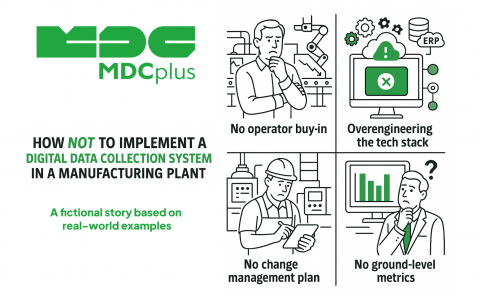

Digital transformation is a buzzword in every manufacturing boardroom. But what often goes unnoticed are the failed or underwhelming implementations that silently drain budgets, frustrate teams, and reinforce resistance to change. Let's walk this through with MDCplus.

03 April 2025

The integration of digital data analysis into Root Cause Analysis represents a transformative shift in manufacturing, enabling more accurate, efficient, and proactive identification of issues. By leveraging comprehensive data collection, advanced analytics, and real-time monitoring, manufacturers can enhance product quality, reduce downtime, and maintain a competitive edge in the industry.

02 April 2025

Today, KUKA is a global leader in robotics and automation, offering solutions across industries such as automotive, healthcare, and manufacturing. Here's a breakdown of the top choices in each category.

01 April 2025

Is it easy to concentrate solely on hitting production targets and meeting deadlines? No. However, when you overlook regular checks on your processes, small issues can quickly grow into major obstacles.

31 March 2025

The Precision Machining Technology Show (PMTS), scheduled for April 1-3, 2025, is the premier event for professionals in the precision machining and manufacturing industries.

28 March 2025

The age of digital data processing is already here, and, as many other aspects of life, have some regulations to follow. Let's learn about GDPR standard with MDCplus team.