- Main

- Blog

Blog

04 April 2025

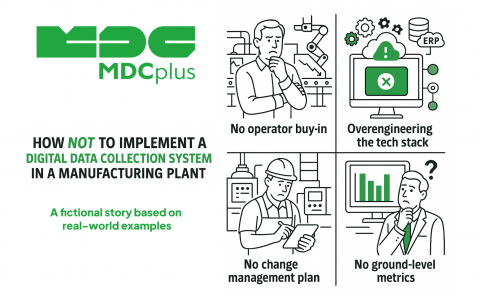

Digital transformation is a buzzword in every manufacturing boardroom. But what often goes unnoticed are the failed or underwhelming implementations that silently drain budgets, frustrate teams, and reinforce resistance to change. Let's walk this through with MDCplus.

03 April 2025

The integration of digital data analysis into Root Cause Analysis represents a transformative shift in manufacturing, enabling more accurate, efficient, and proactive identification of issues. By leveraging comprehensive data collection, advanced analytics, and real-time monitoring, manufacturers can enhance product quality, reduce downtime, and maintain a competitive edge in the industry.

02 April 2025

Today, KUKA is a global leader in robotics and automation, offering solutions across industries such as automotive, healthcare, and manufacturing. Here's a breakdown of the top choices in each category.

01 April 2025

Is it easy to concentrate solely on hitting production targets and meeting deadlines? No. However, when you overlook regular checks on your processes, small issues can quickly grow into major obstacles.

31 March 2025

The Precision Machining Technology Show (PMTS), scheduled for April 1-3, 2025, is the premier event for professionals in the precision machining and manufacturing industries.

28 March 2025

The age of digital data processing is already here, and, as many other aspects of life, have some regulations to follow. Let's learn about GDPR standard with MDCplus team.

27 March 2025

Below is an updated guide to the key standards and practical steps manufacturers should follow when implementing data collection solutions.

26 March 2025

Understanding why downtime happens and how to prevent it is key to keeping production running smoothly, and let's learn it together with MDCplus

25 March 2025

This article highlights three standout Mazak CNC machines in each category: beginner-friendly, advanced, and versatile models.

24 March 2025

This article is a curated list of notable manufacturing events scheduled for 2025 throughout US, which are worth to visit.