Top 3 SCADA Systems For Oil & Gas

Comparison of SCADA Systems for Oil and Gas

Here is a comprehensive comparison of Rockwell Automation FactoryTalk, Schneider Electric SCADAPack, and Honeywell Experion SCADA, focusing on their integration capabilities, pros, and cons for applications in pipeline monitoring, drilling operations, and refinery management.

Rockwell Automation FactoryTalk

Integration Information:

- Integrates seamlessly with Rockwell Automation’s PLCs and PlantPAx Distributed Control System (DCS).

- Supports OPC UA and MQTT for connectivity with third-party systems and IoT platforms.

- Enables real-time data integration across upstream (exploration, drilling) and downstream (refining, distribution) processes.

Pros:

- Advanced alarm management for critical oil and gas operations.

- Real-time data integration for better visibility across supply chains.

- Scalable for both small-scale drilling operations and large refineries.

- Strong analytics and reporting features tailored for process optimization.

Cons:

- Primarily optimized for Rockwell hardware, limiting flexibility with other vendors.

- High implementation costs for full-scale deployments.

- Requires trained operators familiar with Rockwell systems for optimal use.

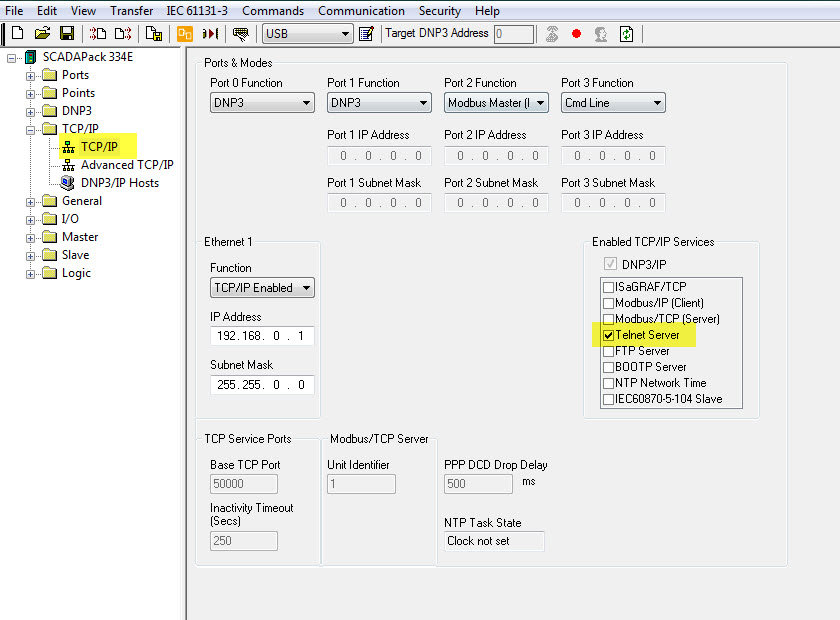

Schneider Electric SCADAPack

Integration Information:

- Specialized for remote monitoring and control in field operations like pipelines and wellheads.

- Integrates with Schneider’s EcoStruxure platform for IoT-enabled capabilities and cloud analytics.

- Supports Modbus, DNP3, and IEC 60870-5 protocols for remote operations.

Pros:

- Excellent for remote and distributed field monitoring, such as pipelines and offshore rigs.

- IoT-enabled, offering enhanced connectivity and remote access for real-time data.

- Low power consumption and rugged design suitable for harsh environments.

- Flexible deployment options with support for edge computing.

Cons:

- Limited scalability for large refineries compared to other SCADA systems.

- Not as feature-rich for advanced analytics and process optimization.

- Dependency on Schneider’s ecosystem for full functionality.

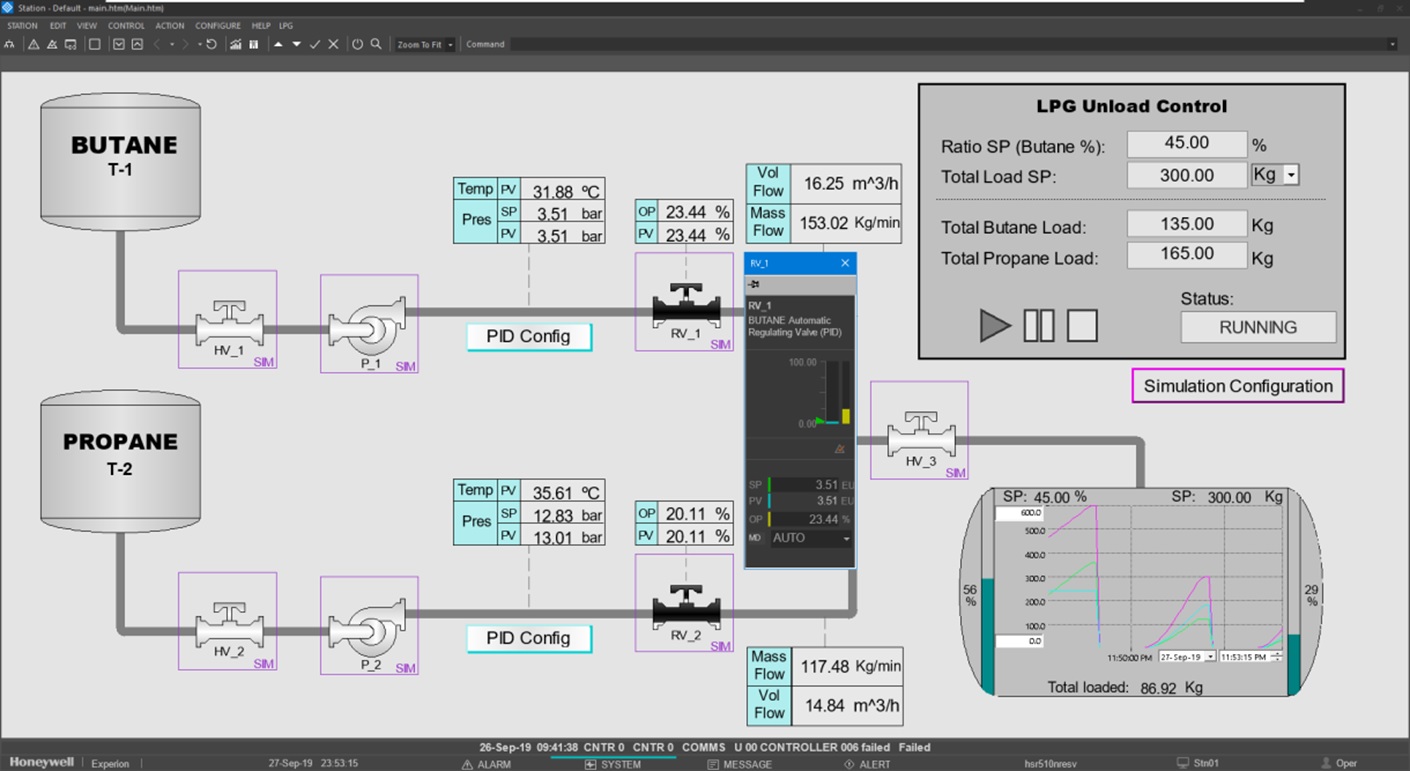

Honeywell Experion SCADA

Integration Information:

- Combines SCADA with Distributed Control Systems (DCS) and Safety Instrumented Systems (SIS).

- Integrates seamlessly with Honeywell’s broader automation and safety product suite.

- Provides advanced analytics powered by machine learning for predictive maintenance and optimization.

Pros:

- Ideal for complex refinery and pipeline systems requiring advanced safety and control.

- Real-time optimization tools reduce downtime and improve operational efficiency.

- Scalable for both small field operations and large, multi-site refineries.

- Strong alarm management and compliance features for regulatory adherence.

Cons:

- High cost of implementation and operation.

- Requires significant training for operators to leverage its advanced features.

- Best suited for organizations already using Honeywell’s automation ecosystem.

Right SCADA system is vital asset for optimizing oil and gas operations. Rockwell Automation FactoryTalk is best suited for integrated upstream and downstream processes, offering strong real-time data integration and advanced alarm management. Schneider Electric SCADAPack excels in remote pipeline monitoring and field operations, particularly in rugged and distributed environments. Honeywell Experion SCADA is ideal for large-scale, complex refinery systems that require advanced safety integration and real-time optimization. Select the system based on the scale and complexity of your operations, and whether your focus is on remote monitoring, refinery management, or comprehensive process visibility.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, We empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?

Other articles

Here’s a breakdown of the most popular online services and communities machinists actually use when troubleshooting CNC problems — ranked by reputation, depth, and real engagement.