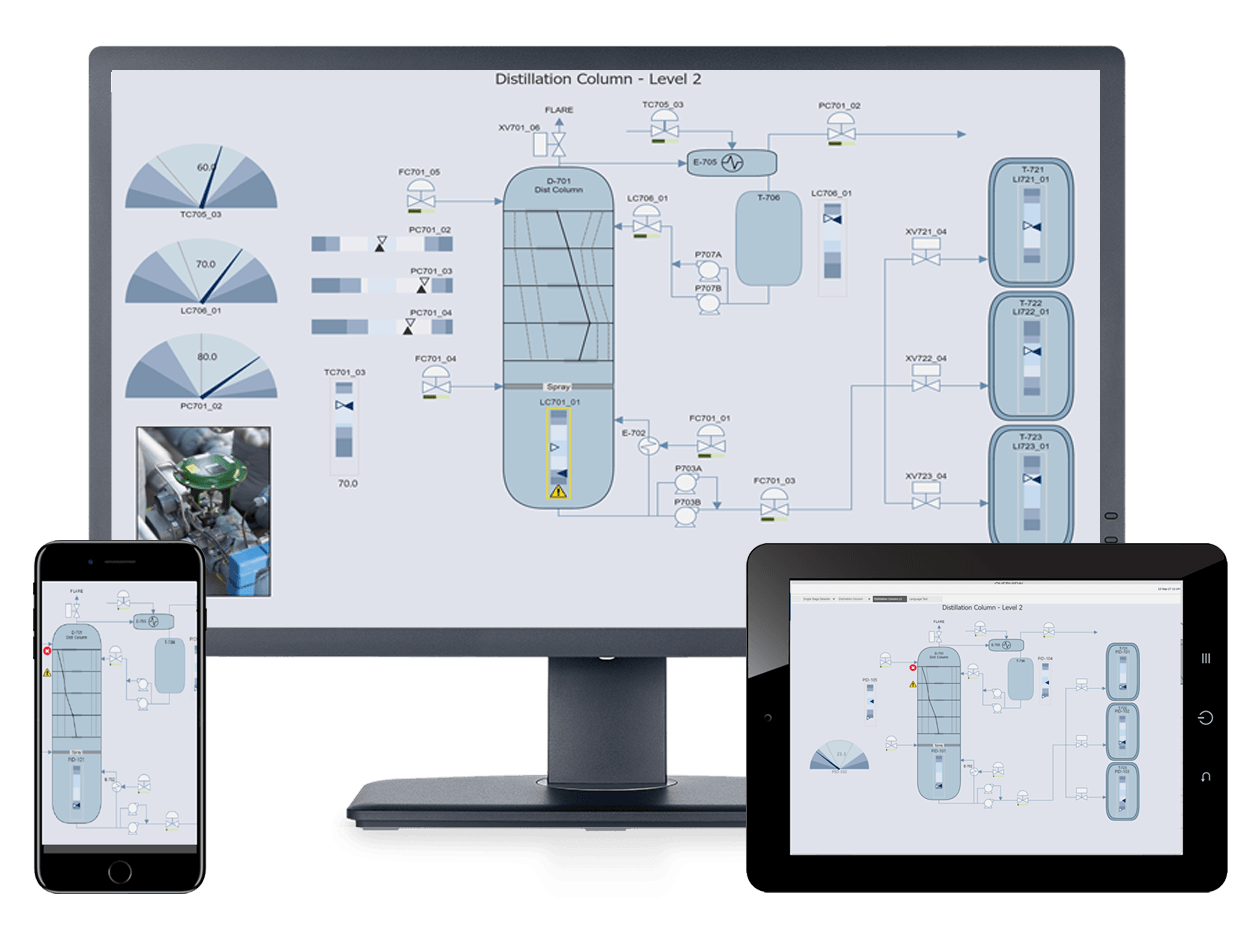

Top 3 SCADA Systems For Process Manufacturing

Comparison of SCADA Systems for Process Manufacturing

Here's a detailed comparison of Emerson DeltaV, AVEVA System Platform, and Honeywell Experion PKS for process manufacturing, focusing on integration, pros, and cons.

Emerson DeltaV

Integration Information:

- Tailored for continuous and batch processes with tight integration into Distributed Control Systems (DCS).

- Supports integration with advanced process control (APC) systems and field devices via HART and FOUNDATION Fieldbus.

- Provides native compatibility with Emerson’s broader automation solutions.

Pros:

- Specifically designed for complex process industries (e.g., chemicals, food, pharmaceuticals).

- Advanced analytics capabilities for process optimization and anomaly detection.

- Strong reliability for critical operations in continuous manufacturing.

- Intuitive batch control features, simplifying recipe management.

Cons:

- Expensive, especially for smaller operations.

- Limited flexibility with third-party hardware and software outside Emerson’s ecosystem.

- Proprietary system can lead to vendor lock-in.

AVEVA System Platform

Integration Information:

- Provides seamless integration with other AVEVA products and third-party systems using OPC UA.

- Strong support for MES, ERP, and cloud-based systems.

- Modular and scalable, making it suitable for large, multi-site process manufacturing.

Pros:

- Enterprise-wide scalability, ideal for large-scale operations.

- Centralized monitoring with robust analytics and reporting tools.

- Supports cloud connectivity and IoT integration for modern manufacturing environments.

- Flexible and adaptable to various industries, including pharmaceuticals and food production.

Cons:

- Requires technical expertise for deployment and customization.

- Higher licensing and implementation costs compared to simpler SCADA systems.

- Complexity can be overwhelming for small-scale manufacturers.

Honeywell Experion PKS

Integration Information:

- Combines SCADA and Distributed Control System (DCS) functionalities for seamless process control.

- Supports integration with Honeywell’s safety systems, energy management, and IIoT devices.

- Robust support for real-time optimization using advanced analytics and machine learning.

Pros:

- Ideal for high-risk industries like oil & gas and pharmaceuticals due to integrated safety systems.

- Real-time optimization features enhance operational efficiency and reduce downtime.

- Scalable across diverse processes, from small plants to global operations.

- Advanced alarm management ensures safe and efficient operations.

Cons:

- Proprietary system may limit integration flexibility with non-Honeywell products.

- Premium pricing, making it less accessible for smaller manufacturers.

- Steeper learning curve for operators unfamiliar with Honeywell systems.

Summing up, Emerson DeltaV is best for industries needing reliable batch and continuous processing, especially those already using Emerson’s DCS solutions. AVEVA System Platform is ideal for large-scale, multi-site operations that require centralized monitoring and enterprise integration. Honeywell Experion PKS is a top choice for high-risk industries, offering robust safety features, real-time optimization, and seamless integration with Honeywell's broader automation solutions. The choice should be guided by your industry's requirements, operational scale, and priorities for safety, flexibility, or enterprise-level control.

About MDCplus

Our key features are real-time machine monitoring for swift issue resolution, power consumption tracking to promote sustainability, computerized maintenance management to reduce downtime, and vibration diagnostics for predictive maintenance. MDCplus's solutions are tailored for diverse industries, including aerospace, automotive, precision machining, and heavy industry. By delivering actionable insights and fostering seamless integration, We empower manufacturers to boost Overall Equipment Effectiveness (OEE), reduce operational costs, and achieve sustainable growth along with future planning.

Ready to increase your OEE, get clearer vision of your shop floor, and predict sustainably?